Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

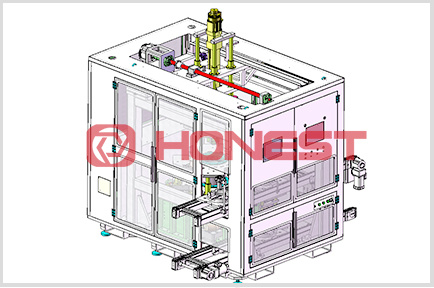

Hairpin Motor Twisting Machine

This equipment is used in the field of hairpin motors. The equipment is connected with the front and rear machine heads by means of pallet transportation + conveying line, which mainly completes the automatic transfer of the stator to flaring position, the automatic paper protection of the paper protection needle, and automatic flaring. The equipment is highly automated and intelligent. The modular and flexible design makes the application of this device more flexible, with wide product compatibility, greatly reducing the production cost of the enterprise and improving its competitive advantage.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Through reasonable logic program design, the continuity and stability of the equipment in the production process are ensured.

-

02

There is a press-in detection of the stator into the twisting wire mold on the equipment and real-time monitoring.

-

03

The servo control of the upper and lower layers of paper protection needle discs effectively protects the position accuracy of insulating paper and copper wires.

-

04

Servo press-fitting and servo twisting wire parameters compensate each other and precisely control the change of twisting wire angle and height.

-

05

Precise wire twisting: Servo wire twisting + screw guide provides super torque and wire twisting accuracy.

-

06

The twisted wire is equipped with multi-layer power, which can be switched automatically.

Equipment parameters

-

Efficiency

-

Less than 90 S/PCS

-

Compatible products

-

Outer diameter 180-220, stack thickness 80-160

-

Conversion time

-

30Min

-

Qualified rate

-

≥98%

-

Voltage

-

Total incoming line three-phase AC 380V 50HZ single machine AC 220V/380V 50HZ.

-

Air pressure

- 0.45MPa~0.65MPa

-

Power

-

15.5KW

-

Automaticity

-

Fully automatic

-

Size

-

1.5m*2.3m*2.0m

Recommended Products