Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Electric Hub Motor Winding Machine

This winding machine is engineered for producing wheel hub motors used in electric motorcycles. It adopts high-speed flyer winding technology to deliver accurate and consistent coil formation. The system features automatic wire cutting at both the beginning and end of the winding cycle, effectively preventing copper wire waste.

ONLINE CONSULTATIONproduct details

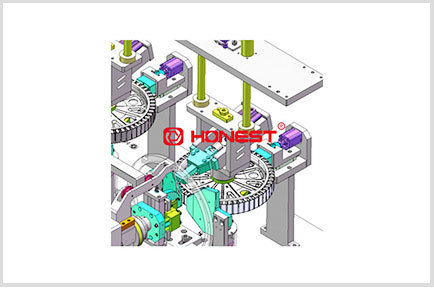

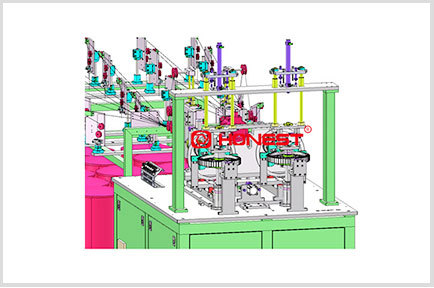

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Automatically trims wire ends to reduce copper usage and minimize material loss.

-

02

Easily adaptable to various hub motor designs, ensuring fast and flexible model changes.

-

03

Dual-station stator winding design boosts productivity, ideal for multi-strand coil applications.

-

04

Zero copper waste during the winding process, helping reduce overall production costs.

-

05

Disconnection detection system triggers alarms instantly for rapid troubleshooting.

-

06

Delivers high-speed, smooth winding performance—compatible with diverse slot structures.

Equipment parameters

-

Number of Stations

-

2 Stations

-

Maximum speed of Flyer

-

1000 RPM

-

Product Size

-

D250*H100 (mm)

-

Maximum Number of Winding Strands

-

20 Strands

-

Wire Diameter Range

-

0.3~0.8mm

-

Whether to Strip Paint

-

No

-

Application Area

-

Electric Motorcycle

Recommended Products