Solution

Honest devotes to providing customized solution.

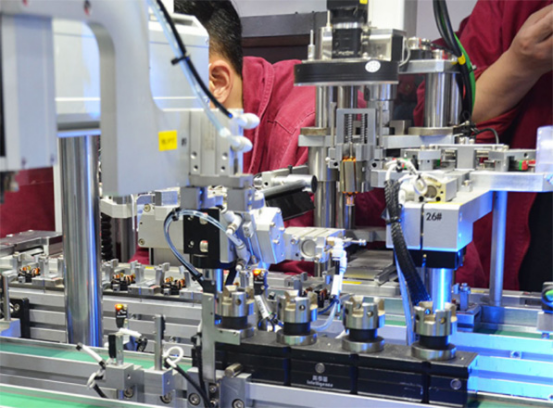

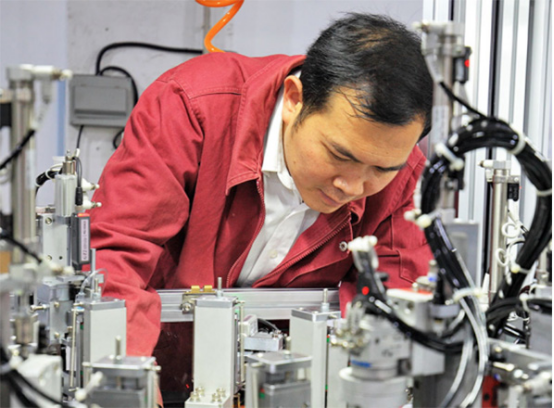

Motor Assembly Equipment Solution

HONEST has 16 years of experience in Non-standard equipment custom motor assembly equipment and has mature cases in the assembly process of DC brush and brushless motors. At present, the whole line of motor assembly line can reach the fastest 2 seconds out of a finished product and can be compatible with more than 40 kinds of motor assembly production. The automation level is high, only 1 to 2 people are needed to load and unload the whole line. We also have data collection system and use MES system to manage the production execution process.

Equipment Quality Requirements:

Important processes are equipped with automatic inspection of the merits of the motor and automatic sorting of the motor, through machine vision instead of manual inspection, inspection efficiency is greatly improved. Motor inspection appearance process in the factory, the use of machine vision system automatic inspection function, with fast, accurate, high-efficiency characteristics, the product 360-degree appearance inspection by the industrial camera and vision automatic inspection system with the automatic vision inspection machine, whether the wiring is reasonably judged by the system software analysis accurately determine, the whole process is less than 1 second if there are defective products will be selected for improvement to ensure the quality of the products.

Equipment Safety Protection, Error-proof.

Configured with special safety grating, safety door lock, etc. for personal safety protection, with open door safety protection function, with air pressure safety protection function, real-time prompting various misoperation, reject state, etc.; when abnormal, display abnormal alarm on the screen, prompting abnormal position, convenient for manual operation.

Equipment Delivery Time.

After more than 10 years of precipitation, a large number of mechanisms have been designed by modularization and standardization, which has laid the foundation for efficient equipment development and high-cost performance. While the delivery time in the industry is generally 6 months, we can shorten it to 4 months through standardized operations in company departments. At the same time, when the equipment is delivered, our engineers will follow the equipment to the customer's factory and guide the installation and commissioning of the equipment throughout the process, providing a full range of one-on-one practical operation and technical training until the trial operation of the whole production line successfully with the standard.