News Center

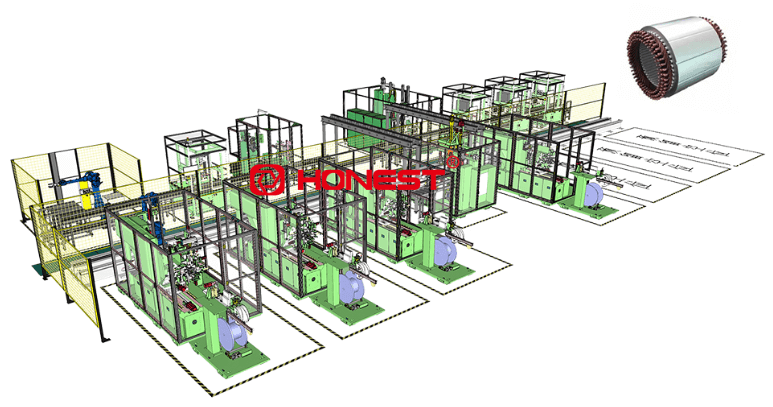

HONEST’s Efficient Hairpin Stator Assembly Line

Published on.

2024-09-07 10:16

Source

The stator of an electric motor is the stationary component of the motor. It consists of three main components: the stator core, the stator winding, and the motor frame. The primary function of the stator is to generate a rotating magnetic field, which interacts with the rotor to initiate rotation. When current is passed through the stator winding, an electromagnetic field within the stator is created.

The direction and intensity of this field are determined by the current in the winding and their arrangement. The stator is one of the core components of an electric motor, bearing the important tasks of motor rotation and power output.

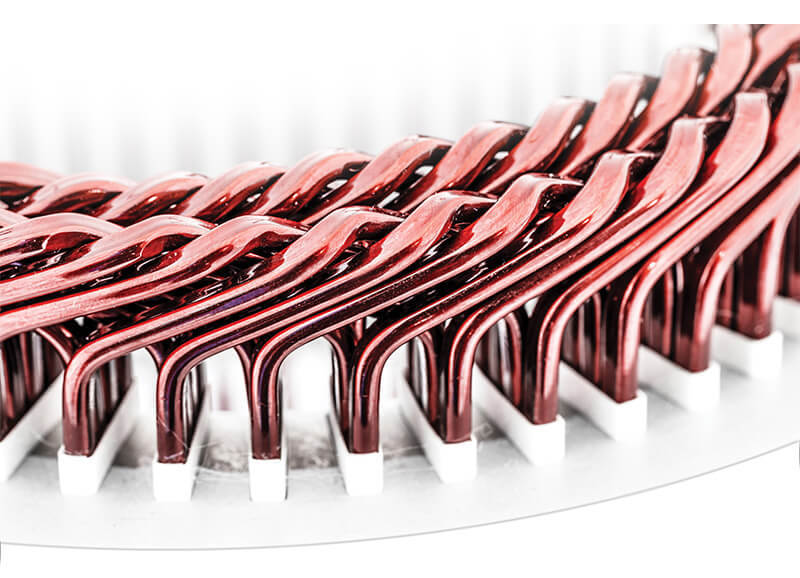

Hairpin stator are a critical component in the drive motors of new energy vehicles. They utilize flat-shaped conductors for winding, offering advantages such as higher slot fill factor, lower losses, and better heat dissipation compared to traditional round wire motors. These advantages not only enhance the overall efficiency of the hairpin motor but also provide strong support for its application in new energy vehicles.

Key Production Equipment for Hairpin Stator Production Line

Before designing the hairpin stator production line, HONEST’s team of experts will first engage in detailed and in-depth communications with the customer. This includes confirming the material transfer distance, the layout of production equipment, and the area occupied by the production line. Through meticulous communication, we customize a solution that perfectly aligns with the customer’s requirements.

In the field of motor manufacturing, every step of the process is crucial. HONEST is committed to providing customers with efficient and high-quality production equipment through advanced automation technology. Below is the key production equipment for our hairpin stator production line.

1. Iron Core Loading & Stator Winding Machine

HONEST’s core loading machine, within the production process, utilizes robotic precision to grasp the stator and place it onto the stator height inspection station. This stage is equipped with a 3D vision monitoring system to ensure the accuracy of recognition and positioning. Before the stator winding, the equipment performs stop positioning and code reading operations to ensure the smooth progress of subsequent processes.

2. Insulation Paper Inserting Machine

HONEST’s insulation paper inserting machine uses a mechanical arm to grip the core and place it into the slot paper waiting station for positioning before proceeding with the paper insertion operation. The O/B can be switched according to actual needs during the operation. Before inserting the insulation paper, the equipment automatically performs creasing treatment, followed by a servo motor-controlled paper feeding process. Closed-loop control technology ensures high precision in paper feeding. Each slot paper is inserted one by one, and the machine completes all slot paper insertions by rotating a full circle. To ensure the performance of the insulation paper, we also configure a standalone machine - a paper drying oven, for drying treatment of the insulation paper.

3. Wire Straightening and Splicing Machine

After the wire enters the equipment, it is automatically straightened. In this process, two sets of straightening wheels with fine-tuning functions are equipped, one set for vertical and one for horizontal direction. During the wire-forming process, mature CNC technology is used to shape the wire, which is compatible and avoids potential damage to the enameled wire during the mold-forming process. HONEST’s wire straightening machine has a high degree of flexibility, capable of completing all wire types for a single stator, effectively saving equipment costs and improving wire insertion efficiency.

4. Hairpin Stator Twisting Machine

HONEST’s stator twisting machine is equipped with a wire protection device to prevent damage to the insulation paper during the twisting process. In the twisting head stage, the stator is fed into the twisting station by a module, and the wire ends are inserted into the twisting mold. Each layer of the twisting mold is independently driven by a servo motor to rotate, while the stator axial servo compensates for the motion, ensuring that the wire ends are precisely twisted according to the set spatial position to complete the end twisting. Our equipment can also set the rebound compensation parameters for the wire to optimize the twisting motion, significantly improving the twisting CT.

Every piece of equipment from HONEST is meticulously designed to ensure that each process is carried out efficiently and smoothly, achieving high-quality and high-efficiency production of products. We are committed to providing specific solutions and high-quality production equipment to meet our customers' production needs. If you are interested in other process equipment of our stator production line, please feel free to contact us, and we will provide you with more detailed information and explanations.

Hairpin Stator Production Line: Technological Applications and Development Trends

The technological innovation and market development of hairpin stator production lines represents a significant trend in the field of industrial automation today. In the electric vehicle (EV) sector, hairpin stators are widely used due to their superior performance. By leveraging advanced automation technologies, these production lines aim to enhance production efficiency, reduce labor costs, and ensure the consistency and reliability of product quality. Below is a detailed introduction to the technological applications and development of hairpin stator production lines.

Technological Application Areas

Hairpin stators, with their high slot fill factor, excellent heat dissipation, and high efficiency, are extensively applied in the electric vehicle sector. As the EV market continues to expand, the demand and performance requirements for hairpin stators are also increasing, which significantly drives innovation and development in the technology of hairpin stator production equipment manufacturers.

Motor Equipment Intelligence

To further enhance motor efficiency and power density, the number of layers and winding design of hairpin coils are continuously optimized. The need for a higher degree of automation in equipment is also growing. The application of automated production lines not only improves production efficiency and saves labor costs but also ensures the consistency and quality of the final products. HONEST’s hairpin stator production line can achieve fully automated production for three-layer six-wire, four-layer eight-wire, and five-layer ten-wire configurations to meet various customer requirements.

The automation of hairpin stator production lines is moving towards a more automated and intelligent direction to meet the growing market demand for hairpin stators. Technological innovation will also continuously drive the upgrading of production lines to meet higher standards of production efficiency and product quality.

Market Analysis of Hairpin Stator Production Lines

With the rapid development of the economy and the acceleration of production automation and intelligence, the automation of hairpin stator production lines is a major trend in the future development of the manufacturing industry. It can effectively improve the production efficiency of enterprises and enhance their competitiveness. In the face of increasing investment in technological innovation and fierce market competition, manufacturers of hairpin stator production lines should actively embrace market dynamics, increase R&D efforts, and design more intelligent automated stator production lines to meet market demands.

Market Supply

Globally, the market size for hairpin stator production lines will continue to expand, especially in key markets such as China, Europe, and North America. It is anticipated that increased investment in technological innovation and R&D will help improve production efficiency, reduce labor costs, and enable enterprises to reduce costs and increase efficiency, enhancing market competitiveness.

As an important supplier of global motor hairpin stator automated production lines, China has many professional motor manufacturers and automation equipment suppliers. With the booming development of the electric vehicle market, local enterprises have not only accumulated rich production technology but also established a complete supply chain system. At the same time, European countries such as Germany and Switzerland, with their leading advantages in automation technology, hold a competitive position in the market.

Market Demand

The booming development of the new energy vehicle industry is the main driving force behind the increasing demand for hairpin stator automated production lines. As governments around the world actively promote the popularization of electric vehicles and introduce various policy supports, the demand for hairpin motors from automobile manufacturers continues to grow, which directly drives the demand for hairpin stator production lines and related production equipment.

The global new energy vehicle market is expected to continue to grow rapidly. Policy support, continuous improvement of infrastructure, and the increasing demand from consumers are all important factors driving the demand for hairpin stator production lines. At the same time, in the wave of industrial automation and intelligent manufacturing, the application of hairpin motors in other industrial fields is also expanding. This not only drives the market demand for hairpin winding stator production lines but also injects new momentum into the development of the entire industry, increasing market competition.[1]

HONEST has extensive experience in the design and manufacturing of hairpin motor automated production lines, committed to providing customers with efficient, high-quality hairpin stator production equipment, and gaining an advantage in fierce market competition. By precisely scheduling production, we achieve shorter delivery cycles, delivering to customer factories as soon as possible, allowing customers to start using them promptly. If you have any requirements for hairpin stator production equipment or automated production lines, please feel free to contact us, and we will provide you with detailed explanations and preliminary quotations.

[1]”2024 Global and China Motor Flat Wire Stator Automation Production Line Market Competition Landscape and Development Prospects Research Report" Accessed. September 3, 2024 from Bossonresearch.com

Previous page

Related News