News Center

Copper Price Up: How Motor Manufacturers Save Wire

Published on.

2025-05-21 08:49

Source

For the motor manufacturing industry, the rise in copper prices directly leads to a significant increase in raw material costs. Taking conventional motors as an example, copper wire, used primarily for winding the stator and rotor, accounts for a large proportion of the total motor cost. The surge in copper prices places substantial financial pressure on motor manufacturers during raw material procurement, causing production costs to continually rise. At the same time, to cope with increasing costs, manufacturers may raise product prices, which can affect their market competitiveness and, in turn, have a profound impact on the overall market structure and development trends of the industry.

In response to the changing landscape of copper price increases, HONEST Automation, a supplier of intelligent motor equipment solutions, leverages technological innovation and smart manufacturing methods to implement various strategies and measures in various scenarios, achieving cost reduction and efficiency improvement.

1. Optimize Production Processes

By introducing advanced automation technologies and equipment, the production process of motor manufacturing is comprehensively optimized. For example, in the motor assembly stage, highly automated assembly lines are employed to achieve integrated operations—from component transportation and assembly to finished product inspection. This automated production method not only improves production efficiency and reduces errors and waste caused by manual operations but also enables precise control over the usage of raw materials such as copper wire, effectively lowering production costs.

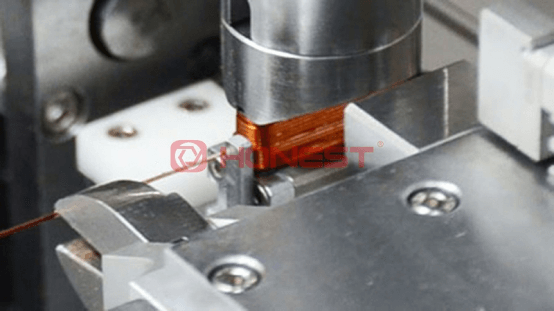

(1) High-Precision Winding Process to Reduce Copper Waste: In fully automatic winding machines, precise control of the winding process can reduce or eliminate wire scrap, thereby saving on copper wire costs.

(2) Improving Slot Fill Rate through New Materials and Processes: HONEST utilizes rectangular cross-section flat conductors, which effectively increase the slot fill rate and the amount of copper wire filled. This enhances the motor’s power density and efficiency within the same motor volume. In addition, HONEST’s new flat wire motor stator straightening and twisting machine features precise independent twisting head parameter design and optimized mold structure, eliminating the need for a straightening process. This avoids copper wire waste caused by traditional straightening procedures, achieving zero copper wire waste.

2. Process Improvement Measures

In motor manufacturing, HONEST Automation continuously pursues innovation and improvement. On one hand, the R&D team optimizes the winding process by refining the winding path and density, resulting in a more uniform distribution of copper wire within the motor windings and improving copper utilization. On the other hand, HONEST actively explores the application of new materials, experimenting with substituting copper with other metals such as aluminum in certain motor components to reduce dependence on copper.

The series of strategies and measures adopted by HONEST Automation to address rising copper prices and reduce copper wire costs fully demonstrates its professional expertise and innovative capabilities as a provider of motor winding and assembly equipment solutions. Through the optimization of production processes and continuous process improvements, HONEST has not only effectively tackled the challenges posed by copper price increases but also contributed to cost reduction and efficiency improvement in the motor manufacturing industry, helping the sector advance steadily amid a complex and ever-changing market environment.

Looking ahead, with ongoing technological advancements and continuous market changes, challenges such as raw material price fluctuations are likely to persist in the long term. HONEST Automation will continue to uphold the philosophy of innovation-driven development, increase R&D investment, and further optimize and upgrade its intelligent equipment. The company will also explore new technologies and methods to reduce raw material costs. At the same time, it will strengthen collaboration and communication with upstream and downstream enterprises to jointly address market risks and drive the motor manufacturing industry to higher levels, contributing more to the development of the global intelligent manufacturing sector.

Related News