Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

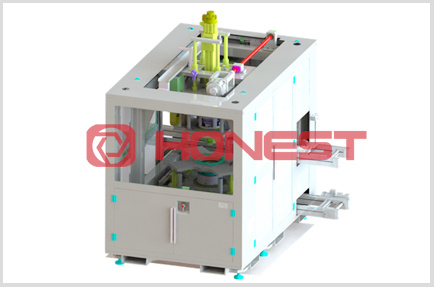

X-Pin Motor Assembly Line

The key processes of the electric vehicle drive motor X-PIN stator assembly line include wire forming, twisting, welding, insulation treatment, etc. HONEST can provide stand-alone, semi-automatic and fully automatic production lines according to customer needs.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

The accuracy of the twisting head mold is guaranteed to ensure that the height of the welding end line is consistent.

-

02

Special clamping tooling to ensure that the wire ends of each solder joint are in a clamped state.

-

03

Less replacement parts, strong versatility.

-

04

Fast conversion.

-

05

Maximize copper wire savings.

-

06

Stable equipment operation, less maintenance, high cost performance.

Equipment parameters

-

Efficiency

-

Up to 60 pcs/H

-

Voltage

-

AC three-phase 380V

-

Air pressure

-

0.4~0.6MPa

-

Qualified rate

-

More than 98%

-

Power

-

40KW

-

Weight

- 14 tons

-

Control method

-

PLC bus control

-

Application field

-

New energy vehicle drive motor

-

Size

-

35 meters (length) X15 meters (width)

Recommended Products