Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

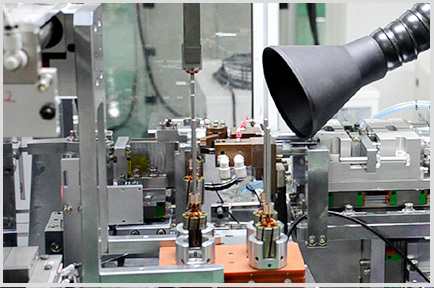

Spot welding machine

The rotor spot welding machine equipment is suitable for rotor shaft diameter Φ2mm-Φ8mm, and can complete multi-stage rotor hook welding. The equipment is delivered to the door for free, and our engineers follow the equipment to the site to guide the installation and commissioning and provide all-around one-to-one practical and technical training.

ONLINE CONSULTATIONProduct details

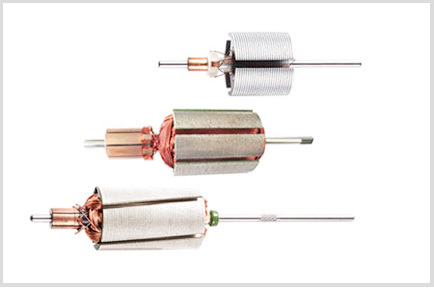

Split-graph

Finished-product-drawing

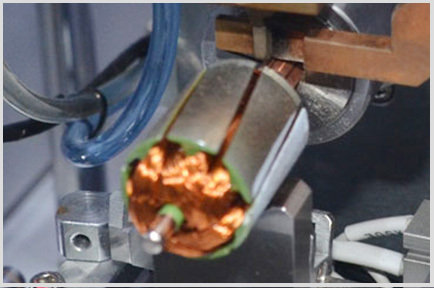

Local graph

Advantages

-

01

Imported welding power source is adopted, and the discharge power is stable.

-

02

It has welding current monitoring and can set the upper and lower limit alarm function.

-

03

Doesn't damage the roundness and step difference of the commutator.

-

04

Stable operation, guaranteed product efficiency and quality.

-

05

Can support the whole production line, also can be customized.

-

06

Provide door-to-door delivery, and our engineers will guide the installation and commissioning.

Equipment parameters

-

Complete process

-

Complete multi-stage rotor hook welding

-

Scope of application

-

Rotor shaft diameter φ2-φ8mm (lock nozzle needs to be replaced)

-

Applicable rotor outer diameter

-

φ100mm (need to replace the rotor positioning seat)

-

Applicable leather temperature

-

125-225℃

-

Welding pressure method

-

Cylinder + spring (optional servo + pressure displacement monitoring)

-

Welding resistance test method

- Completely passed the aging test

-

Welding power source

-

Japanese MIYACHI or AVIO

-

Production output

-

600-1200pcs per hour

-

Power supply

-

Three-phase AC 380V 50HZ

-

Cooling method

-

Water cooling

-

Power

-

12KW

-

Physical dimension

-

750mm(L)*800mm(W*1850mm(H)

Recommended Products