Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

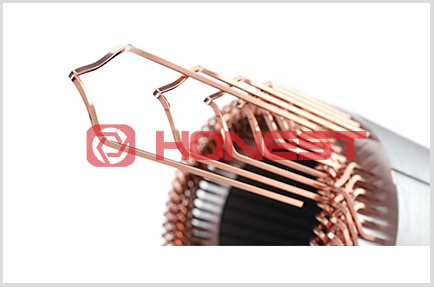

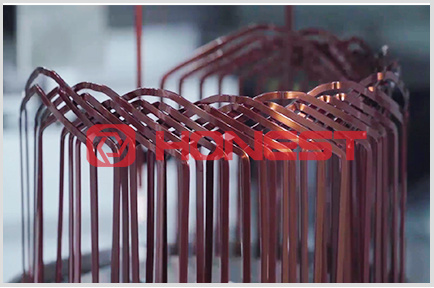

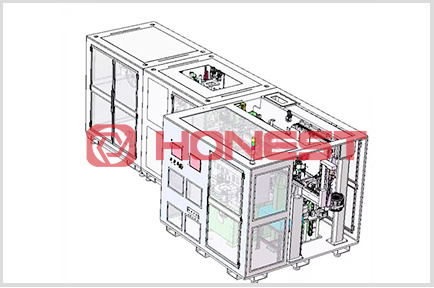

Hairpin Motor Wire Making Machine

This machine is applied in the production of hairpin motors for new energy vehicles. The equipment is highly automated and intelligent. It is equipped with MES system to realize the dynamic information display of production status, production scheduling, material distribution, process parameters (including pressure, displacement, performance parameters, appearance, etc.), statistical analysis of production quality data, equipment operation status and maintenance management, and factory information management of quality traceability system. The modular and flexible design makes the application of this device more flexible, with wide product compatibility, greatly reducing the production cost of the enterprise and improving its competitive advantage.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

2D folding+3D mold production line, with one production machine completing the production of all stator lines.

-

02

Online automatic and fast switching of 3D molds through mold library mode.

-

03

Prompt for feeding when the spool is out of material.

-

04

Hairpin conducts 100% online voltage resistance testing and automatically eliminates any defects.

-

05

Automatic identification of defective incoming wire identification and corresponding hair pin automatic removal.

-

06

Automatic wire insertion and assembly cup, automatically completing the production of the entire stator cup.

Equipment parameters

-

Efficiency

-

approximately 3 seconds/pcs

-

Compatibility

-

Can meet the production requirements for all wires of hairpin motors within 6 wires and 12 layers

-

Exchange time

-

One click automatic switching

-

Yield rate

-

More than 95%

-

Crop growth rate

-

≥ 90% of the entire line

-

Voltage

- Main incoming three-phase AC 380V 50HZ, single machine AC 220V/380V 50HZ

-

Operating air pressure

-

0.45MPa~0.65MPa

-

Power

-

About 10KW of the entire machine

-

Control method

-

PLC+touch screen

Recommended Products