Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

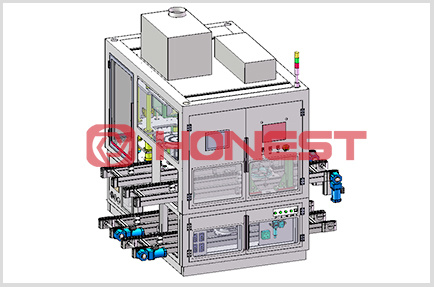

Hairpin Motor Assembly Welding Machine

The welding machine is a production line automation equipment that performs light welding on the stator that has been inserted into the wire. It has a high degree of intelligence, and is equipped with MES system. The equipment automatically fixes the wire and can realize automatic clamping and welding protection. What’s more, it is equipped with a cleaning mechanism to effectively prevent splashing pollution to the stator during welding. The equipment adopts a modular and flexible design, which makes the application of the program more flexible and has a wide range of product compatibility, which greatly reduces the cost of production change of the enterprise and improves the competitive advantage of the enterprise.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Equipped with high-precision sensors, visual inspection systems, for precise welding of copper wires.

-

02

The equipment automatically fixes the wire and can realize automatic clamping and welding protection.

-

03

It is equipped with a cleaning mechanism to effectively prevent splashing pollution to the stator during welding

-

04

Fool-proof and mistake-proof.

-

05

Sensor monitoring and alarm system can effectively avoid wrong actions and ensure smooth production and personal safety.

-

06

Through reasonable logic program design, the continuity and stability of the equipment in the production process are ensured.

Equipment parameters

-

Equipment size

-

L2400 X W2300 X H2500mm

-

Efficiency

-

96 S/pcs

-

Conversion time

-

30Min

-

Qualified rate

-

≥95%

-

Utilization rate

-

≥90%

-

Voltage

- total incoming line three-phase AC 380V 50HZ single machine AC 220V/380V 50HZ

-

Air pressure

-

0.45MPa~0.65MPa

-

Power

-

The whole line is about 15KW

-

Number of people needed

-

Unmanned

Recommended Products