Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

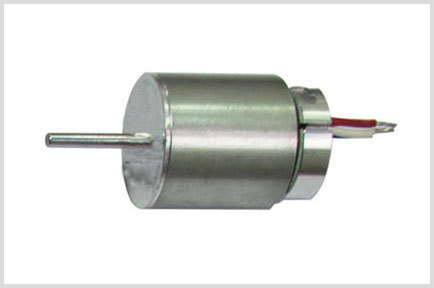

Household appliance motor production line

1. The magnet assembly is equipped with inner diameter and leak detection, and the defective is automatically discharged 2.Dry glue. Has a wire- broken detection and alarm function 3. The shaft is pressed into the rotor. Configure a high-precision glue dispenser to control the amount of glue and fueling 4. The press-fit size is stable and the consistency is good. 5. Rotor double-station dynamic balance detection 6. Compared with the original production line: save 32 people and improve the efficiency by 3 to 4 times

ONLINE CONSULTATIONproduct details

Split-graph

Finished-product-drawing

Local graph

product details

-

01

Base section: install the circuit board, press bearing, glue ,dry,etc.

-

02

Base section: install the circuit board, press bearing, glue ,dry,etc.

-

03

Base section: install the circuit board, press bearing, glue ,dry,etc.

Equipment parameters

-

The scope of application

-

Household appliances motor

-

Loading mode

-

The robot arm automatically grabs and feeds the material

-

Unloading mode

-

Unloaded by robot arm

-

Production efficiency

-

5 seconds / PCS

-

Qualification rate

-

≥98% (except for factors such as poor materials or manual debugging)

-

Gas pressure

-

0.4 ~ 0.6MPa

-

Power supply

-

AC220V / 380V 50HZ

-

Frame size

-

22 (L) * 1.3 (W) * 1.8 (H) m

Recommended Products