Products

Customized solutions for motor production lines

16-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

New energy vehicles rotor assembly equipment

The equipment is used for the assembly of four rotors of air conditioner compressor of new energy vehicles. The assembly process includes rivet length detection, rivet assembly,installing upper counterweight disc, upper anti-damage plate assembly, iron core assembly, magnetic steel assembly,installing bottom counterweight disc, rivet flanging diameter detection, crankshaft pressing, crank pin pressing NG removal, 4-axis robot arms discharging, etc.

ONLINE CONSULTATIONproduct details

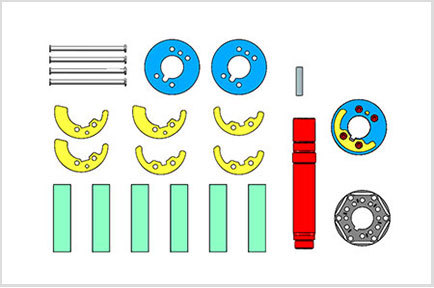

Split graph

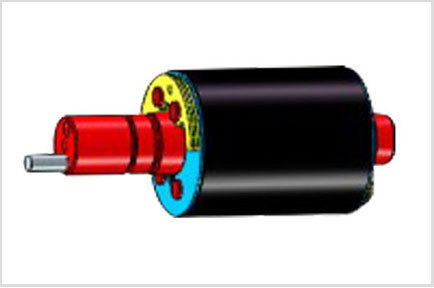

Finished product drawing

Local graph

Advantages

-

01

MES manufacturing execution system is adopted for the equipment to provide data management, production process control, data integration and decomposition and other management modules for the enterprise

-

02

The electrical system adopts OMRON PLC, which can be fully automatic, semi-automatic and manual operation

-

03

Quickily change mould and one switch to change production type

-

04

Panasonic servo motor, baoyiwei servo press, Yamaha mechanical arms, SMC pneumatic and other hardwares are selected as standard parts

-

05

High positioning accuracy and flexibility

-

06

High precision, good rigidity, vibration resistance and long service life.

Equipment parameters

-

Production efficiency

-

120 PCS / hour

-

Loading mode

-

Fed by trolley, vibrating plate and spring clip

-

Unloading mode

-

Place the product sequentially

-

Power

-

13.2kw

-

Gas pressure

-

0.4 ~ 0.6MPa

-

Power supply

-

380V

Recommended Products