Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

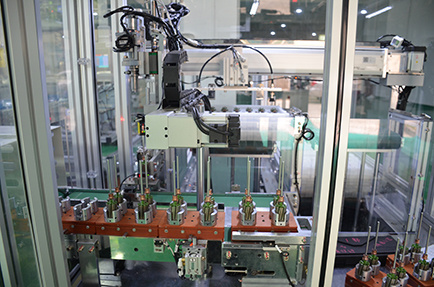

Double Flyer Rotor Assembly Line

This double flyer rotor production line is 3or 4 times more efficient than others on the market today. Fully automatic loading and unloading, only one person is required to operate. the equipment is compact,has a smaller footprint and uses the space reasonably. it consists of core loading, winding, spot welding, polishing, inspection, unloading and other processes

ONLINE CONSULTATIONproduct details

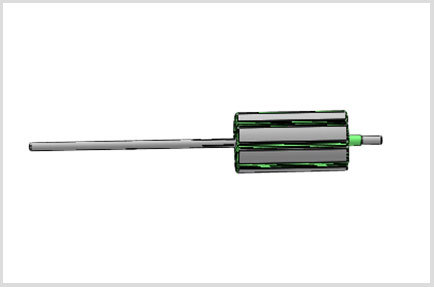

Split-graph

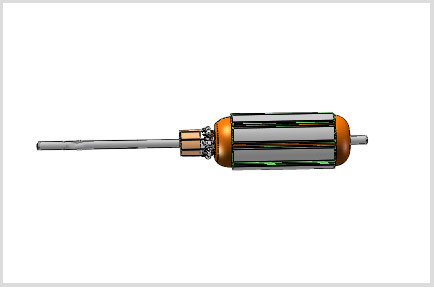

Finished-product-drawing

Local graph

Advantages

-

01

4-station forks wind and 4 stations load and unload material. At the same time, automatically handle wire head and tail quickly.Don’t waste copper wire. Defect rate is under 5%.

-

02

Different process equipment could be added to rotor assembly phase.

-

03

Could trace the finished rotor to the corresponding head and fork to and mark

-

04

Spot welding uses single spot welding way. Monitor pressure. Electrode life measurement can be set.

-

05

The armature air-cooled mechanism could reduces the welding temperature to normal temperature quickly and smoothly.

-

06

The armature tester can be specified by the customer.After turning, the height gap between each commutator piece is equal to or less than 0.005mm.

Equipment parameters

-

Production efficiency

-

8s/pcs

-

Scope of application

-

Customizable

-

Loading mode

-

The mechanical arm clips the rotor from the positioning plate and loads it.

-

Unloading mode

-

Transported by Belt

-

Gas pressure

-

0.4-0.6MPa

-

Power supply

-

220v

Recommended Products