Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

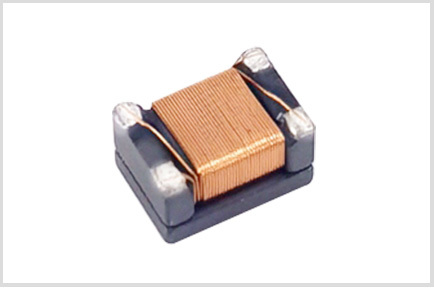

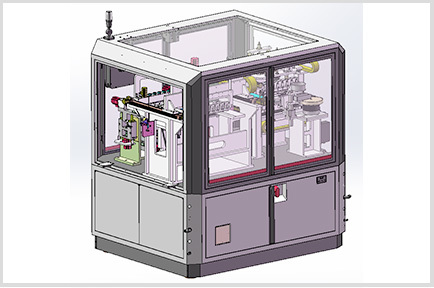

Common Mode Choke Winding Equipment

Common mode choke winding equipment processes include automatic feeding, winding, spot welding, and blanking. It can complete 2P, 4P, 6P, 8P and other specifications of pad magnetic cores, realize winding spot welding integration, suitable for 5819, 5817, 4532, 3225, 3216 and other size SMD inductors, single and double wires, can be switched freely, it can be switched at will according to customer requirements.

ONLINE CONSULTATIONproduct details

Finished-product-drawing

Finished-product-drawing

Local graph

Advantages

-

01

10-axis high precision winding at the same time, high efficiency.

-

02

Use Yaskawa motion controller and Yaskawa servo motor.

-

03

Independent R&D of precision winding and arranging system, independent R&D of the welding system.

-

04

Use Japanese THK precision screw and guide rail to ensure the stability of the whole machine.

-

05

Can be equipped with CCD detection and discharge and MES system.

-

06

The whole machine can only be manually loaded, and the others are automatically completed.

Equipment parameters

-

Production efficiency

-

Up to 2000PCS per Hour

-

Spindle speed

-

1500MAX

-

Axis spacing

-

40MM

-

Voltage

-

380V,30A

-

Air pressure

-

0.5-0.7Mpa

-

Applicable wire diameter

-

0.02-0.12

-

Size

-

1.7m*3.0m*2.0m

Recommended Products