Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

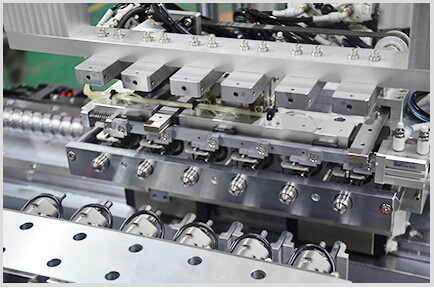

T Core Choke Winding Equipment

The process flow of Tcore choke winding equipment includes: Magnetic core feeding: magnetic core Tcore vibration plate feeding, 6s per pcs. Winding: a flat wire is wound on the magnetic core, the winding method is pair winding, and the hot air is self-adhesive while winding. Wire management: hang the wire neatly, cut off the excess tail wire, and fix it to the magnetic core by welding. Cutting: Cutting the product according to customer requirements, etc.

ONLINE CONSULTATIONproduct details

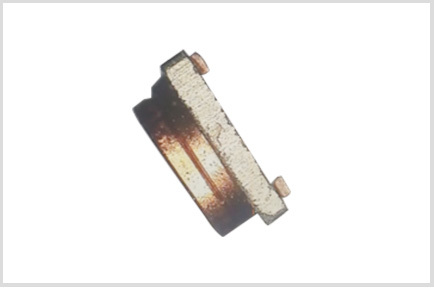

Finished-product-drawing

Finished-product-drawing

Local graph

Advantages

-

01

The servo motor adopts bus control, and the key parts are all independently processed by precision equipment.

-

02

Standard parts adopt top international brands, lifespan management of key parts.

-

03

Only 1 operator is required.

-

04

The output can up to 3000pcs per Hour.

-

05

The qualified product rate can reach more than 99%.

-

06

Non-standard can be customized.

Equipment parameters

-

Production efficiency

-

1.5 seconds per pcs

-

Qualified product rate

-

More than 99%

-

Running time throughout the day

-

More than 95%

-

Number of operators required

-

1 person

-

Voltage

-

AC three-phase 380V

-

Air pressure

-

0.4~0.6MPa

-

Power

-

4KW

-

Control Method

-

PLC Bus Control

-

Size

-

2.5m (length) x 1.5m (width) x 1.9m (height)

-

Application field

-

Smartphones, smart wearables, automobile

Recommended Products