Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

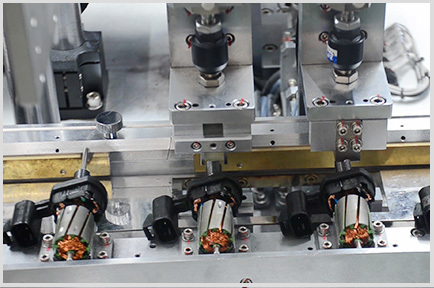

Automobile power window motor assembly line

The motor automation assembly line is used in the field of automotive power windows. The efficiency of the whole line equipment is lower than 5 seconds/PCS, and it is compatible with 5 motors. Its main processes include automatic loading and unloading (rotor, end cover, stator), manipulator handling and moving materials, automatic completion of magnetic ring pressing, worm pressing, bending core correction, stator magnetization and motor assembly, etc. At the same time, the modular and flexible design also makes the application of the program more flexible and has a wide range of product compatibility, which greatly reduces the cost of production conversion for enterprises.

ONLINE CONSULTATIONproduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Reading the two-dimensional code information of the product through a code scanner, a code reader, etc.

-

02

Bind the production process data to the QR code for easy traceability and quality analysis.

-

03

SPC data statistics function.

-

04

Servo module cooperates with manipulator to transport and grab materials, with strong flexibility and high precision.

-

05

Servo motor is used for press-fitting, and the press-fitting process has pressure monitoring to ensure press-fitting accuracy.

-

06

Compatible with five products, rapid transformation by selecting parameters and changing fixtures.

Equipment parameters

-

Exchange time

-

Less than 20 minutes

-

Voltage

-

Three-phase AC 380V 50HZ

-

Air pressure

-

0.45MPa~0.65MPa

-

Power

-

The whole line is about 20KW

-

Qualified product rate

-

More than 99%

-

Full-day time utilization

-

Whole line more than 90%

-

Control method

-

PLC+touch screen

Recommended Products