Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Stator Segmented Winding Equipment

The stator segmented winding equipment is used in the field of brushless DC motors (electronic water pump motors). It mainly completes the winding of the stator core of the brushless motor. It has a wide range of compatibility and can be customized for customers according to customer process requirements. This equipment adopts X, Y, Z three-axis servo linkage and horizontal winding method for winding, supplemented by unique structural design and rigorous logical sequence, to realize automatic loading and unloading, winding, wiring, stripping and trimming.

ONLINE CONSULTATIONproduct details

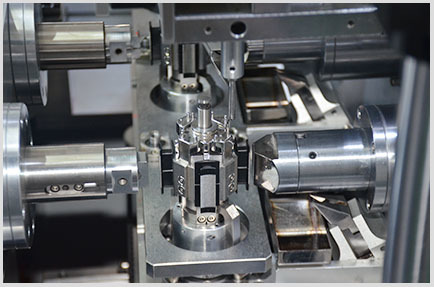

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Adopting double gripping jaw design, switch loading and unloading methods for loading and unloading.

-

02

Save the time of loading and unloading and improve the production efficiency of the equipment.

-

03

Six-station winding, automatic winding, arranging, peeling paint and trimming, no waste wire is generated during the winding process.

-

04

X, Y, Z three-axis servo linkage winding, wiring stroke, paint stripping length.

-

05

Parameters such as the number of pauses can be adjusted to facilitate the control of the line posture.

-

06

Meet the requirements of different winding processes.

Equipment parameters

-

Production efficiency

-

12S per PCS

-

Applicable wire diameter

-

1mm-1.5mm

-

Winding speed

-

600r/min, related to product size and wire diameter, the specific speed should be set according to the product.

-

Scope of application

-

Outer diameter 60mm-100mm, stacking thickness 15mm-50mm

-

Winding method

-

Flat-wound winding, X, Y, Z three-axis servo linkage winding

-

Voltage

-

Three-phase AC 380V 50HZ

-

Size

-

1800(L)*2779(W)*2053(H)mm

Recommended Products