Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

The Controller Motor End Cap Assembly Equipment

The controller motor end cap assembly equipment consists of 5 sets of equipment in a linear arrangement. The main conveyor adopts a double-speed chain, and the modular structure design of each process workstation is suitable for the controller assembly of two products. The design of the entire production line can save 6 operators, reduce the labor cost of the company, but also ensure production efficiency and more stable quality. The main process flow of the equipment includes casing feeding, circuit board material assembly, pre-tightening PCBA screws, fastening heat sinks, crimping heads, fastening PCBA screws and assembling lead injection molded parts, appearance inspection and scanning receivers, etc.

ONLINE CONSULTATIONproduct details

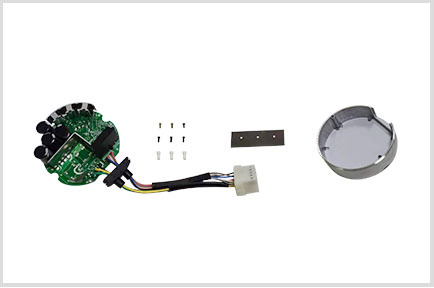

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Servo motor screws are equipped with data display and torque feedback function.

-

02

The modular structure design of each process workstation can operate independently and move separately.

-

03

When a station is suspended, the production can be operated manually.

-

04

Using MES system, the QR code information of the bound product can be obtained by scanning the code, and the data can be traced.

-

05

Visualization of the equipment control cabinet window. When the equipment is working, it has its own lighting, which is convenient for debugging and maintenance.

-

06

Comes with a safety protection lock, and sets the relevant interlock function on the program.

Equipment parameters

-

Production efficiency

-

10.6s /pcs

-

Compatible products

-

2 products

-

Exchange time

-

≤10min

-

Yield rate

-

≥99.9%

-

Power

-

The whole line is about 15KW

-

Control Method

-

PLC + touch screen

-

Dimension

-

1000(L)*3100(W)*2000(H)mm

Recommended Products