Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Automobile water pump motor stator winding machine

Automobile water pump motor stator winding machine is applied in the field of DC brushless motor. (Vehicle water pump motor) The main process contains block stator winding, circular welding, wiring bridge assembly and performance test, etc. High automation line. With RFID function, product traceability. Meanwhile it contains the data storage system. Data is stored in Excel table with report function. All line apply advanced production process with all round visual inspection system. It can improve efficiency and make the quality more stable.

ONLINE CONSULTATIONProduct details

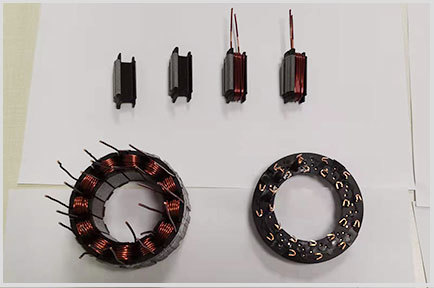

Split-graph

Finished-product-drawing

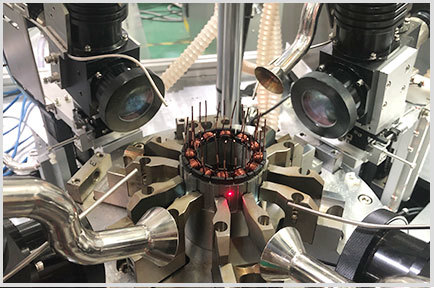

Local graph

Advantages

-

01

Board with RFID sensor for data traceability

-

02

Circular welding, it can weld 4 points at the same time. The length of welding can be adjusted. Configured with visual inspection system.

-

03

Double clamping jaws and switching methods for winding loading and unloading, and six-station winding at the same time

-

04

Modular fixture design, change type fast and convenient.

-

05

Cofigured with 4 GT sensor to detect the diameter when forming. Detect 2 times in height direction and generate concentricity detection.

-

06

Wire bridge applies laser galvanometer welding. Avoiding wire damage caused by high temperature splashes, etc.

Equipment parameters

-

Efficiency

-

All line ≤18s/pcs

-

Voltage

-

AC three-phase 380V

-

Air pressure

-

0.45-0.65MPa

-

Pass rate

-

More than 99%

-

Power

-

All line about 40KW

-

Full-day time utilization

-

More than 95%

-

Control Method

-

PLC + touch screen

-

Physical dimension

-

12(L)* 9(W)* 2.5(H)m

-

Compatiable product

-

Wire diameter of 1-1.5mm, an outer diameter of 60-100mm, and a stack height of 15-50mm

Recommended Products