Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

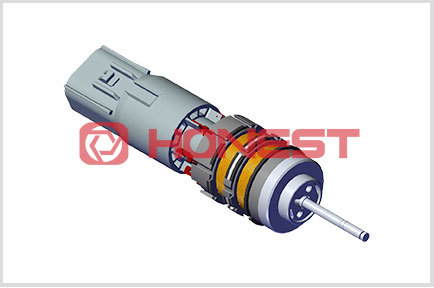

Automotive shock absorber assembly line

Damping adjuster step motor production line is suitable for without front/without rear shock absorber valve. Without front/without rear shock absorber can absorb shock to boost the driving comfortability. Every suspension control accmulator intergrate configure with shock proof actuator. This actuator is composed of 16 steps motor, screw thread, a slide valve, a soft shock absorber valve and hard shock absorber valve. The actuators receive the ECU control signal from the suspension and change the flow channel by slide valve to change flow channel volume to control the shock level. The process contains incoming material inspection, rotor dispensing, visual inspection, magnetic ring heating and solidification, cover cleaning, rotor assembly, base and magnetic part assembly, scanning+ airtightness test, package and other process.

ONLINE CONSULTATIONProduct details

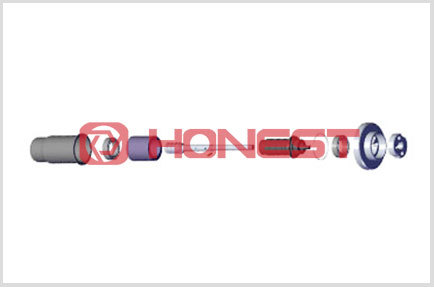

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

With fault self-diagnosis function

-

02

With wrong and shock proof function

-

03

Two types production: online and offline types.

-

04

The equipment has abnormal state monitoring, local data storage and data transmission functions

-

05

The equipment must be produced under the running state of the industrial computer

-

06

The upper computer and the lower computer of the equipment program need to be synchronized

Equipment parameters

-

Efficiency

-

≤ 60 S /PCS(CT)

-

Good rate

-

≥99%

-

Utilization rate

-

≥85%

-

Air pressure

-

0.45MPa~0.65MPa

-

Voltage

-

Three phase AC220V/380V 50HZ

-

Power

-

About 40KW

-

Control Method

-

HMI+PLC+EMS

-

Dimension

-

14m(H)*1.6m(W)* 2.2m(H)

-

Apply area

-

Automotive suspension

Recommended Products