Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

EV Drive Motor Rotor Production Line

The new energy drive motor rotor production line adopts the MES manufacturing execution system to provide enterprises with management modules including manufacturing data management, production process control, underlying data integration analysis, and upper-level data integration and decomposition, so as to create a solid, reliable, comprehensive and feasible manufacturing for enterprises collaborative management platform. This project is used to assemble new energy vehicle drive motor rotors. The whole line adopts modular design, robots automatically load and unload materials, and the production line is highly flexible, providing a one-stop solution for the manufacture of drive motors.

ONLINE CONSULTATIONProduct details

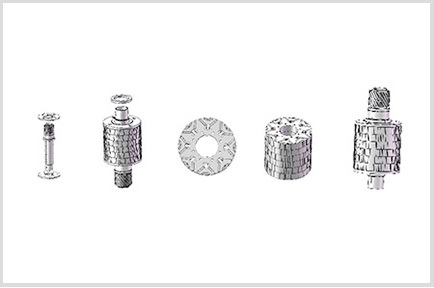

Split-graph

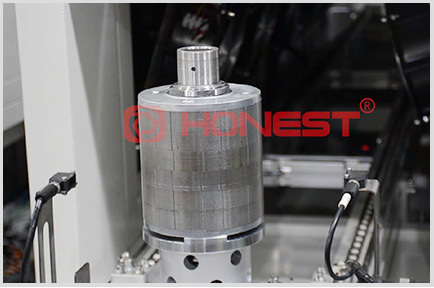

Finished-product-drawing

Local graph

Advantages

-

01

The electrical system adopts Siemens programmable controller 1515PLC.

-

02

The frame is machined as a whole after Fangtong welding, with high precision and good rigidity.

-

03

Non-standard parts adopt chrome-plating of steel parts and paint-baking process of sheet metal parts, which are beautiful and have excellent anti-corrosion.

-

04

The standard parts use hardware such as Siemens servo motors and FANUC manipulators, with high positioning accuracy and flexibility.

-

05

The whole line feeding and handling use six-axis robots, and the production line is highly flexible.

-

06

Each process of the whole line is equipped with high-precision visual inspection system.

Equipment parameters

-

Efficiency

-

128S/PCS

-

Qualification rate

-

98%

-

Voltage

-

380V

-

Power

-

The whole line is about 420KW

-

Control Method

-

PLC+HMI

-

Physical dimension

-

52000(L)*30000(W)*2800(H)mm

-

Compatible products

-

3 styles

-

Application field

-

New energy drive motor

Recommended Products