Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

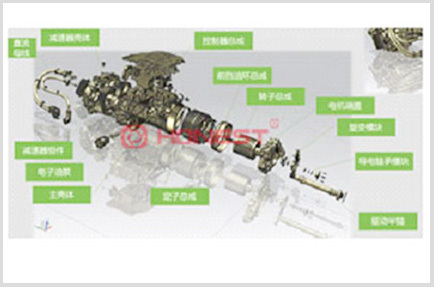

Automotive Drive Motor Assembly Line

The new energy vehicle drive motor assembly equipment process includes rotor press-fit bearing, resolver rotor and pressure plate press-fit, end cover installation positioning pin & elastic wave pad, end cover bearing chamber heating, end cover and rotor assembly, main shell installation front oil deflector, casing heating, stator shrink sleeve, casing cooling, electrical performance test, final tightening and fixing of main reduction gear, cooling of motor assembly, O-ring, casing glue coating, installation of cooler, installation of filter press, filling screw plug, airtight test, product appearance inspection, packaging, storage, etc.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

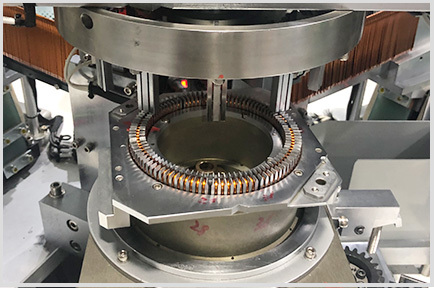

Local graph

Advantages

-

01

The degree of automation is relatively high, and all processes have error-proof and leak-proof detection.

-

02

Configure the whole line data acquisition system to ensure that each process can be traced.

-

03

The newly designed drive assembly structure develops a stable and reliable flexible assembly mechanism to ensure assembly top quality.

-

04

Robot allocation is reasonable to maximize the efficiency of the robot, and automatically connect between the line bodies.

-

05

Digitally manage the production line, process data binding.

-

06

Can be customized according to customer needs.

Equipment parameters

-

Efficiency

-

100S/PCS

-

Qualification rate

-

99.9%

-

Voltage

-

80V/220V

-

Power

-

750KW

-

Control Method

-

Siemens PLC

-

Replacement time

-

30min

-

Physical dimension

-

58(L)*20(W)*2.8(H)m

-

Application field

-

New energy vehicle drive motor

Recommended Products