Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

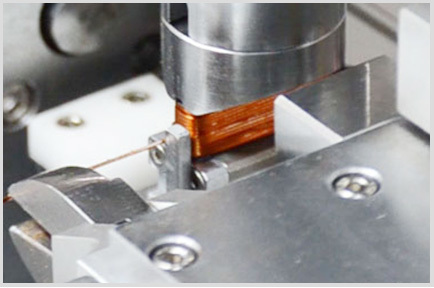

Double-station segmented stator winding machine

The double-station segmented flat wire winding machine manually assembles the stator core and insulating frame, and loads the material to the winding station. The two-hand start function prevents misoperation. The equipment is equipped with X-axis to drive the wire nozzle to move left and right, equipped with Y-axis to drive the wire nozzle to move forward and backward, equipped with Z-axis to drive the wire nozzle to move up and down, and equipped with V-axis to drive the winding spindle to rotate to achieve precise wire arrangement.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Double station winding, improving efficiency.

-

02

Equipped with fine injection dispensing valve, automatic dispensing and fixing of the tail line after winding.

-

03

Flexible and modular design, neat appearance, flexible structure, and wider compatibility.

-

04

Equipped with a split servo tensioner, the tension is adjustable and controllable, and it is equipped with a broken wire alarm function.

-

05

Automatic thread trimming and shaping of thread head and thread tail.

-

06

Configure UV curing lamp to cure the glue.

Equipment parameters

-

Efficiency

-

20S/PCS

-

Applicable wire diameter

-

0.78*0.78mm (including the thickness of the surface insulation layer)

-

Winding speed

-

600r/min, related to product size and wire diameter, the specific speed should be given according to the product.

-

Compatible range

-

3 products

-

End of line treatment

-

End of line dispensing and fixing

-

Power supply

-

AC220V/380V 50HZ

-

Physical dimension

-

1194(L)*1975(W)*2038(H)mm

Recommended Products