Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Closed Loop Stepper Motor Assembly Line

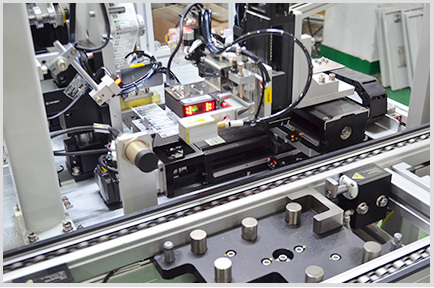

The closed-loop stepper motor assembly line mainly consists of three major functions: PCB board and code disc glue coating, back cover and side cover screw locking, and artificial abnormal sound detection. The closed-loop stepper motor assembly line provides a flexible and powerful guarantee for enterprises to improve production efficiency and product quality and reduce production costs. The main processes of the equipment include manual assembly of PCB and code disc, screw glue, PCB screw lock, code disc screw lock, encoder cover screw lock, crimping seat screw lock, performance test, cutting and other processes.

ONLINE CONSULTATIONProduct details

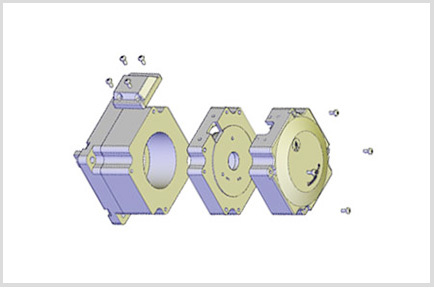

Split-graph

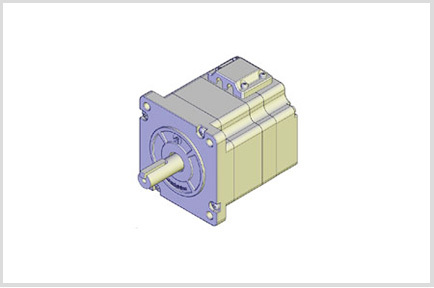

Finished-product-drawing

Local graph

Advantages

-

01

Using servo motor with precision screw module mechanism to apply glue.

-

02

The screwing station has torque and angle monitoring.

-

03

Double-layer liftable double-speed chain.

-

04

Compatible with the assembly of various stepper motor products.

-

05

Convenient human-computer interaction and flexible structure.

-

06

The equipment is easy to operate.

Equipment parameters

-

Efficiency

-

≤24 seconds/PCS

-

Voltage

-

AC380V/AC220V 50HZ

-

Air pressure

-

0.4~0.7Mpa

-

Power

-

The power of the whole line is about 14kw

-

Size

-

20000(L)*2000(W)*1800(H)mm The height of the silent room is 2300mm (estimated)

-

Control method

- Man-machine interface (touch screen), programmable logic controller PLC (or motion controller), communication module.

-

Utilization rate

-

≥90%

-

Scope of application

-

Stepper motor

Recommended Products