Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Segmented Stator Assembly Line

The segmented stator assembly line is designed for segmented stator winding, core assembly, and busbar installation, providing an efficient and integrated motor assembly line. It features an industrial control data acquisition system for comprehensive production process traceability and integrates functions such as vision inspection, material floating and tipping detection, missing component identification, pressure monitoring, and welding inspection. These ensure error prevention and consistent product quality. The flexible design allows for easy upgrades and adjustments to meet future production needs. Contact us now to get a tailored solution and start your journey to efficient production with ease!

ONLINE CONSULTATIONproduct details

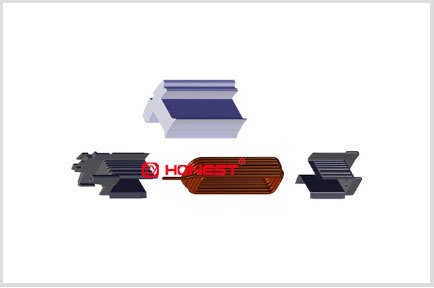

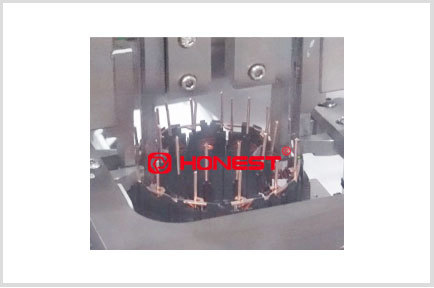

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Reasonable logic program design to complete various complex assembly, inspection and other functions.

-

02

The equipment is ergonomically designed and easy to operate.

-

03

Foolproof and error-proof. Includes program interlocks, profiling jigs, guiding mechanisms, and protective mechanisms.

-

04

The sensor monitoring and alarm system throughout the entire production process effectively avoids the occurrence of erroneous actions.

-

05

Equipped with high-precision sensors, visual inspection systems, etc., to prevent leakage, insufficient installation, wrong installation and post-installation quality inspection.

-

06

Each process can run independently, and a single process failure can jump to the next process to continue working.

Equipment parameters

-

Production efficiency

-

≤ 15 S/PCS (CT)

-

Compatible products

-

6 models

-

Changeover time

-

15-30 minutes

-

Voltage

-

three-phase/AC380V/50HZ

-

Air pressure

-

0.4~0.7Mpa

-

Power

-

130kw

-

Control method

-

PLC+HMI

Recommended Products