News Center

How to Choose Hairpin Motor Production Equipment Manufacturer

Published on.

2025-01-07 14:29

Source

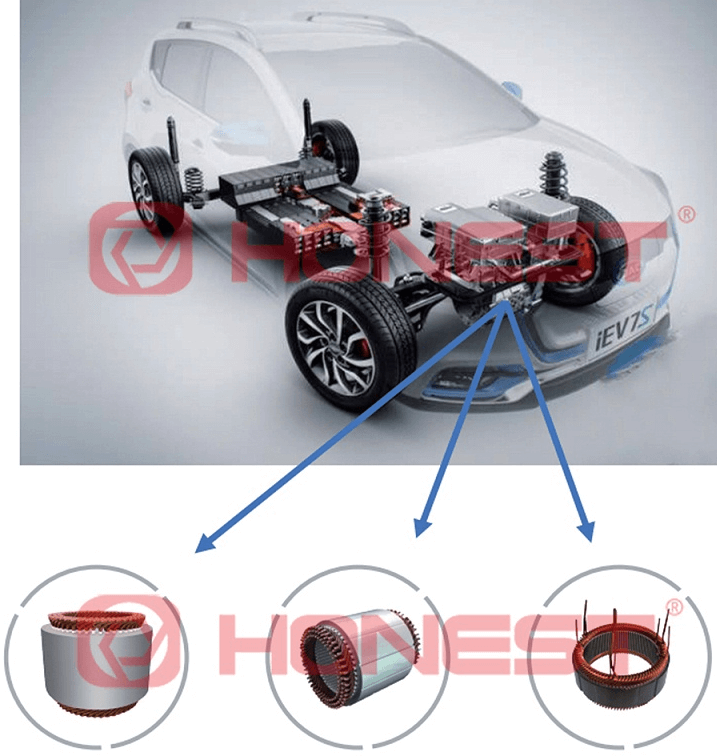

Choosing a high-quality hairpin motor manufacturing supplier is crucial to ensuring product quality, improving production efficiency and reducing production costs. The following are some key strategies that can help companies choose the best among many suppliers.

1. Clarify needs and accurately position

First, companies need to clarify their own production needs, including production scale, product type, technical specifications and budget range. These needs will directly guide the company's choice of suppliers. Based on the needs, companies should set a clear set of selection criteria covering production capacity, technical strength, quality control, price rationality and after-sales service.

2. In-depth research and strength assessment

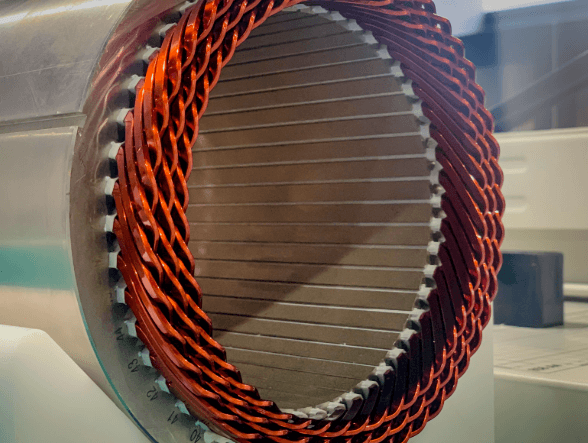

Technical strength and industry qualifications: Investigate whether the supplier has the ability to design, manufacture and debug flat wire motor production lines, understand the professional background of its technical team, R&D achievements and industry experience, and ensure that the supplier can provide products that meet or even exceed industry standards.

Production experience and R&D strength: Check the supplier's historical project cases, especially the successful cases related to flat wire motor production lines, and evaluate the supplier's performance in production management, quality control and delivery capabilities through case analysis.

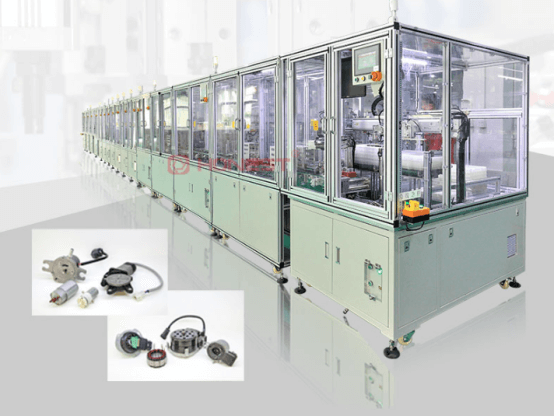

Quality control system: Understand whether the supplier has established a complete quality management system, such as modern production lines and testing equipment, to ensure quality control of products during the production process.

3. On-site inspection and personal experience

After initially screening potential suppliers, it is a crucial step to actually inspect their production sites and equipment. By visiting the production line, observing the process flow, and communicating with technical personnel, you can more intuitively understand the supplier's production capacity, technical level and corporate culture. During the on-site inspection, companies can focus on the following points:

Production efficiency and capacity requirements: Understand the cycle time of the production line, that is, the time interval required to produce a motor, to ensure that the production line can meet the company's production efficiency and capacity requirements.

Product quality and precision: Whether the quality inspection equipment and processes used in the production line can monitor the deviations in dimensions, electrical parameters, etc. in real time during product production, and promptly correct or eliminate unqualified products.

Cost-effectiveness: Weigh procurement costs, operating costs, maintenance costs, etc. to ensure that the equipment procurement cost matches the expected production benefits.

4. Pay attention to after-sales service and support

High-quality after-sales service is the key to ensuring the long-term stable operation of the production line. Enterprises should pay attention to the after-sales service provided by suppliers, including but not limited to technical support, maintenance, spare parts supply and emergency response mechanisms. A good after-sales service system can reduce the risk of production interruption and improve overall operational efficiency.

5. Comprehensive evaluation, cost-benefit analysis

After collecting and analyzing information from multiple suppliers, conduct a comprehensive evaluation. Not only should the direct procurement cost be considered, but also the operating cost (such as energy consumption and maintenance costs), the benefits of improved production efficiency, and the potential cost of technology upgrades. Through cost-benefit analysis, select the supplier with the best cost-effectiveness.

6. Establish long-term cooperative relationships

Suppliers should not only focus on short-term benefits but should focus on establishing long-term and stable cooperative relationships. Therefore, before making a final decision, the supplier's willingness to cooperate, communication efficiency, and compatibility with corporate culture should be evaluated to lay a good foundation for future cooperation.

In short, selecting the best manufacturing supplier of hairpin motor production equipment is a complex and meticulous process, which requires enterprises to consider from multiple dimensions. As one of the suppliers of many flat wire motor production lines, HONEST Automation is committed to providing digital and intelligent motor assembly overall solutions for various industries, focusing on technological innovation and quality control to ensure that each production line can reach the industry-leading level. At the same time, we have a complete after-sales service system to quickly respond to corporate inquiries. In the future, we look forward to working with more industry partners to jointly promote the development of new energy hairpin motor production line manufacturing.

Related News