News Center

Servo Press Machine Buying Guide: Use Data to Save Money and Make the Right Choice

Published on.

2025-03-18 14:41

Source

As a high-precision, intelligent pressure processing equipment in modern industry, servo press is widely used in the fields of automotive parts assembly, electronic component packaging, precision stamping, etc. Its core advantage lies in the precise control of pressure, speed and position through servo motors, which greatly improves production efficiency and product quality. However, facing the diverse servo press models in the market, how to scientifically select the best cost-effective model has become a key challenge for customers.

First of all, we need to understand the working principle of the servo press machine.

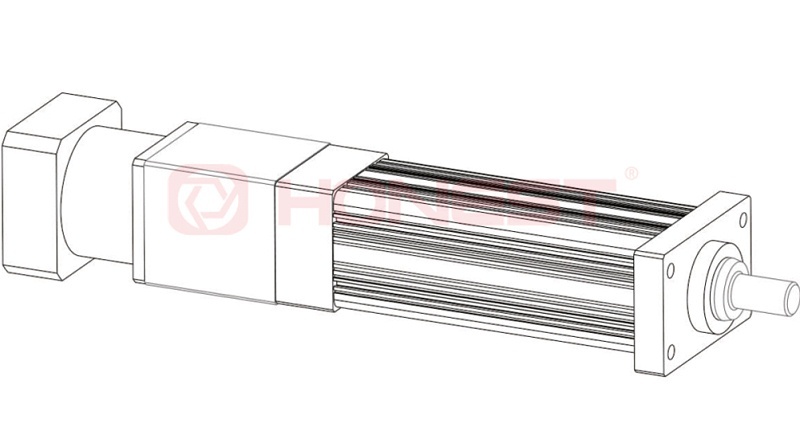

As a high-precision pressure processing equipment based on servo motor drive, the servo press is mainly composed of servo motor, mechanical transmission device, sensor and other core parts. Its working principle combines servo control technology and mechanical transmission technology, which can adjust pressure, speed and displacement in real time to ensure the stability and repeatability of each stroke.

In a servo press, the mechanical transmission device is the core component that connects the servo motor and the actuator and plays a key role in converting the servo motor's rotary motion into linear motion. (In simple terms, the mechanical transmission device is like a "middleman.") Its performance will directly affect the press's accuracy, speed, and load capacity.

Common types include recirculating ball screws, sliding lead screws and planetary roller screws, each with its own characteristics and suitable for different application scenarios.

Their Functions and Advantages:

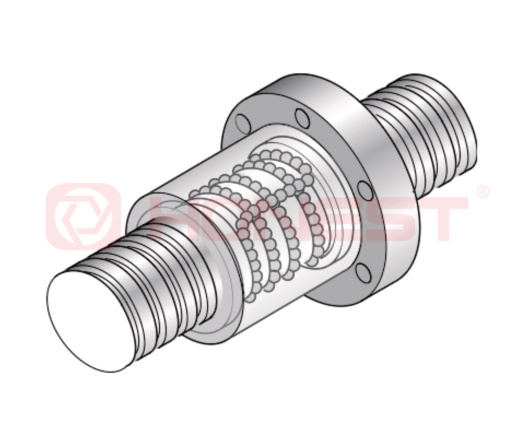

1. Circulating ball screw (BS): It is composed of a screw, a nut, a steel ball, a preload plate, a reverser, and a dust collector. The load is transferred from the spindle screw to the nut through the roller, and the rotational motion is converted into linear motion. (In layman's terms: the ball rolls between the screw and the nut, and the rotational force of the motor is smoothly converted into linear thrust, thereby pushing the load to move). It has high precision, reversibility and high efficiency, and can meet the needs of most industrial production sites, with high-cost performance. It is suitable for industrial automation equipment, CNC machine tools, precision instruments and other places with high requirements for precision and efficiency.

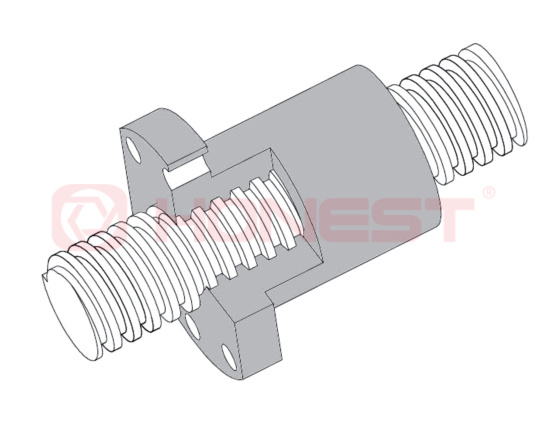

2. Sliding ladder screw (AS): It mainly relies on the oil film between the nut and the screw to produce relative sliding work, and the sliding friction completes the linear motion. (It is like putting an oil film between two objects. When one object rotates, the other object will slide with the oil film.) It has good self-locking properties and will not slide easily due to external forces. At the same time, it has an intermittent working system, which means that it does not need to run continuously, which can effectively reduce wear and heat and extend the service lifespan. The structure is simple and the cost is relatively low. It is suitable for simple mechanical transmission devices, small equipment, and intermittent working applications that require self-locking properties and costs.

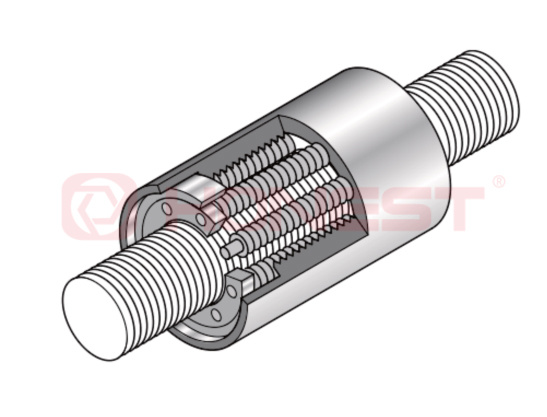

3. Planetary roller screw (RS): The load is transferred from the threaded spindle to the mother (roller) through 6-8 small threaded roller screw convex thread edges. (Specifically: when the threaded spindle rotates, the small threaded roller screw convex thread edge of the planetary roller screw interacts with the threaded spindle to convert the rotational motion into linear motion, thereby driving the object connected to the threaded spindle to do linear motion) It has fast response speed, high acceleration, ultra-long service life, high load occasions, and can work stably under large loads. Suitable for those that require fast response, high acceleration, long life and high load capabilities.

Based on the comparison of cost performance and application scenarios: Circulating ball screw (BS) > Sliding lead screw (AS) < Planetary roller screw (RS).

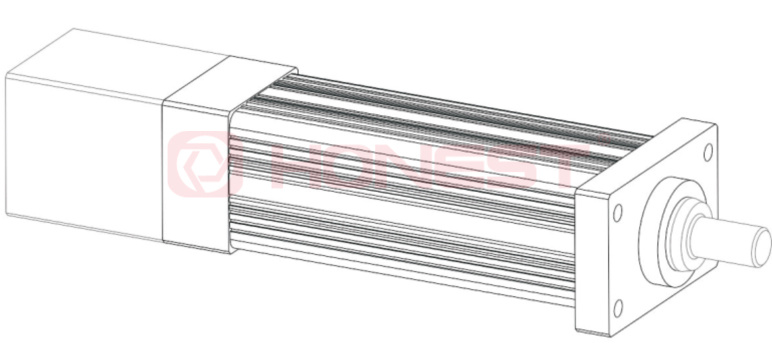

After understanding the types of mechanical transmission devices, let's take a look at the assembly form. The main function of the assembly form is to better adapt to different installation spaces and working requirements, optimize transmission efficiency and load capacity, and at the same time ensure the stability and reliability of the equipment to meet the specific needs of various industrial applications scenarios. Common assembly forms can be divided into: D-type assembly direct-connected cylinder body, B-type return cylinder body, DR-type direct-connected cylinder body with planetary reduction, and B-R-type return cylinder body with planetary reduction.

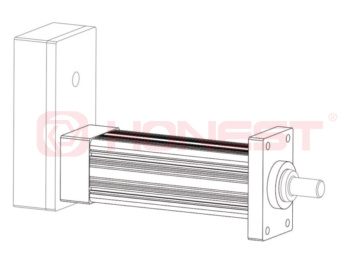

"D" type assembly (directly connected to the cylinder): installed through the coupling housing, no reduction ratio, because there is no reducer, the speed and torque output by the motor are directly transmitted to the screw, and the transmission efficiency is high. (In layman's terms: directly connecting the screw to the cylinder, compact structure, high transmission efficiency, suitable for applications with limited space and high requirements for straightness and precision)

Type "B" (folded cylinder): parallel assembly; by folding the cylinder back to install, a longer stroke can be achieved in a limited space, suitable for occasions where a longer stroke is required but the installation space is limited.

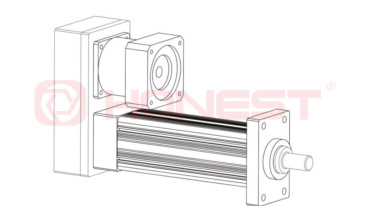

"DR" type (direct-connected cylinder with planetary reducer): direct-connected assembly; combines the assembly method of planetary reducer and direct-connected cylinder, which can provide higher torque output and speed adjustment range, and is suitable for occasions requiring high precision and high load capacity.

"B-R" type (with planetary reduction reversing cylinder): parallel assembly; combining the planetary reducer with the reversing cylinder, it has the torque amplification advantage of the planetary reducer and can achieve a longer stroke in a limited space. It is suitable for applications with high space and torque requirements.

In mechanical transmission devices, we can see that the choice of transmission type and assembly form directly determines the performance, efficiency and applicable scenarios of the equipment. The choice of these two is most important for the performance matching and application scenario adaptability of subsequent equipment. However, in addition to the selection of transmission devices, the selection of servo presses also needs to comprehensively consider key factors such as pressure requirements, stroke length, and speed requirements.

These selection factors jointly determine whether the servo press machine can meet the needs of specific application scenarios and ensure that the equipment operates in an efficient, stable and precise state. In this regard, HONEST Automation has launched various standard models of servo presses based on different types of mechanical transmission devices and their assembly forms to meet the diverse needs of customers. Welcome to leave a message for consultation.

The selection of a servo press is a complex but crucial process involving multiple key selection factors. The correct selection can not only maximize the performance of the equipment, but also significantly improve production efficiency, extend equipment life, and reduce long-term operating costs. On the contrary, improper selection may cause the equipment to fail to meet production needs, and even affect product quality and production stability.

With the continuous development of industrial automation, servo press technology will move towards higher precision, higher efficiency and more intelligent direction. HONEST Automation will continue to be committed to providing customers with high-performance, cost-effective servo press solutions. From selection consultation to R&D and customization, we will provide you with one-stop technical support.

Related News