News Center

In-Depth Understanding: Types, Advantages, and Considerations of Automotive Electric Pumps

Published on.

2024-06-14 14:19

Source

With the rapid development of the automotive industry towards electrification and intelligence, the application of electric pumps in vehicles is becoming increasingly widespread. This article provides a detailed introduction to the working principles, types, and applications of automotive electric pumps.

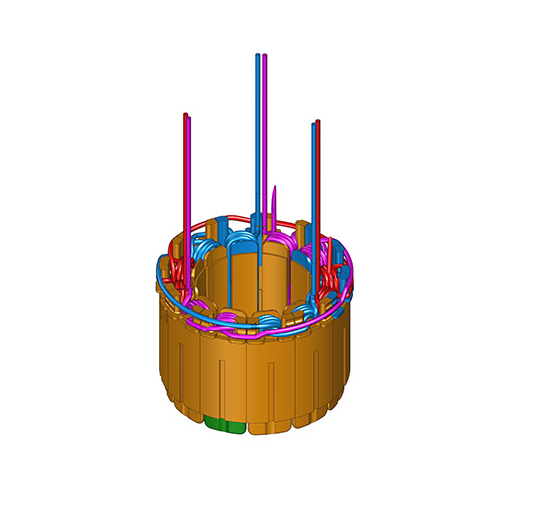

Electric pumps, which are driven by electricity, are sophisticated mechanical devices composed of key components such as the pump body, discharge pipe, pump base, submersible motor (including cables), and starting protection devices. The pump body is the working part of the submersible pump, consisting of the intake pipe, guide shell, check valve, pump shaft, and impeller, among other parts. There are two methods for fixing the impeller on the shaft.

A. Advantages of Electric Pumps

Precise control: Electric pumps can precisely control flow and pressure to meet various working requirements.

Rapid Response: Electric pumps start and stop quickly, responding swiftly to changes in system demands.

Low Maintenance: Compared to hydraulic pumps, electric pumps have lower maintenance costs and longer service life.

High Reliability: The simple design of electric pumps results in a lower failure rate.

Environmentally Friendly: Electric pumps operate quietly, with no risk of leakage, making them eco-friendly.

High Energy Efficiency: Under proper design and usage conditions, electric pumps can offer high energy efficiency.

Easy Integration: Electric pumps are easily integrated into modern automotive electronic control systems.

B. Disadvantages of Electric Pumps

Cost Issues: The initial investment cost of electric pumps is slightly higher than that of traditional mechanical pumps.

Dependence on Electricity: Electric pumps rely on a stable power supply, and insufficient power may affect performance.

Thermal Management: Under high-load conditions, electric pumps may generate more heat, requiring appropriate cooling measures.

Size and Weight: Some high-power electric pumps may be larger and heavier, affecting the overall vehicle design.

Electromagnetic Interference: Electric pumps may generate electromagnetic interference during operation, necessitating consideration of electromagnetic compatibility issues.

C. Working Principle

The impeller is installed inside the pump casing and secured to the pump shaft, which is directly driven by the motor. The pump casing has a liquid suction pipe in the center. Liquid enters the pump through the bottom valve and suction pipe. The liquid discharge port on the pump casing is connected to the discharge pipe.

Before starting the pump, the pump casing is filled with the liquid to be transported; after starting, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate accordingly. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the periphery and gains energy, leaving the periphery of the impeller at high speed and entering the spiral pump casing. In the spiral casing, the liquid slows down due to the gradual expansion of the flow channel, converting some kinetic energy into static pressure energy, and finally flows into the discharge pipeline at a higher pressure, sent to the required location. As the liquid moves from the center to the periphery of the impeller, a certain vacuum is formed at the center of the impeller. Due to the pressure at the pump inlet, the liquid is continuously pressed into the impeller. It can be seen that as long as the impeller keeps rotating, the liquid will be continuously sucked in and discharged.

D. Design Considerations for Electric Pumps

Maximizing Efficiency: The design of electric pumps aims to maximize energy conversion efficiency and reduce energy loss.

Enhancing Reliability: High-quality materials and sealing techniques are used to ensure that the pump can operate stably and normally under harsh conditions.

Noise Control Optimization: Vibration and noise are reduced through optimized design to improve ride comfort.

Compact Design: Electric pumps are typically designed to be compact to fit into limited installation spaces.

Multifunctionality Adaptation: Although each electric pump has specific applications, many pump designs allow them to work under various fluid and pressure conditions.

E. Types of Electric Pumps

Different types of electric pumps each have their characteristics and advantages, and they are typically classified as follows:

1. Fuel Pump

It is responsible for drawing fuel from the vehicle’s fuel tank and delivering it to the engine’s fuel system. This is a key component for the normal operation of the engine as it ensures a continuous supply of fuel.

Type: Usually a centrifugal pump or a gear pump.

Function: Delivers fuel from the fuel tank to the engine’s fuel system.

Features: Requires stable fuel flow at low pressure to ensure efficient engine operation.

2. Coolant Pump

It circulates coolant in the engine cooling system, helping to dissipate the heat generated by the engine during combustion. This pump is an essential part of maintaining engine temperature stability and preventing overheating.

Type: Centrifugal pump.

Function: Circulates coolant in the engine cooling system to help with heat dissipation.

Features: It needs to work stably at high temperatures, usually driven by the engine’s crankshaft, but in some modern vehicles, an electric coolant pump may be used for increased efficiency and control precision.

3. Power Steering Pump

It provides hydraulic oil for the power steering system, reducing the force required by the driver to steer, and improving driving comfort and vehicle handling.

Type: Gear pump or vane pump.

Function: It provides hydraulic pressure for the power steering system to assist with steering operations.

Features: It needs to provide sufficient hydraulic pressure to ensure the ease and responsiveness of steering.

4. Brake Booster Pump

It provides the necessary hydraulic pressure for the braking system, allowing the driver to press the brake pedal more easily and achieve effective braking.

Type: Electric vane pump.

Function: It provides hydraulic pressure for the brake assist system to assist with braking operations.

Features: It requires rapid response to ensure quick deceleration in emergency situations.

5. Oil Pump

It circulates engine oil within the engine, lubricating the various components, and reducing friction and wear in heat dissipation and engine cleaning.

Type: Gear pump or rotor pump.

Function: It circulates engine oil for lubrication, cooling, and cleaning within the engine.

Features: It needs to continuously and stably provide engine oil throughout the engine’s startup and operation.

6. Electric Water Pump

In some modern vehicles, electric water pumps may be used for cooling systems, especially for cooling batteries and motors in electric vehicles. This pump helps maintain the batteries and motors at optimal working temperatures, improving efficiency and extending service life.

Type: Centrifugal Pump.

Function: It may be used for auxiliary cooling of batteries or motors in some hybrid or electric vehicles.

Features: It is typically controlled by an Electronic Control Unit (ECU) for precise temperature management.

7. Vacuum Pump

In some modern vehicles, vacuum pumps are used to provide brake assist or assist other systems that require a vacuum source. With the proliferation of turbocharged and direct-injection engines, traditional vacuum sources may be insufficient, so electric vacuum pumps are used to provide the necessary vacuum.

Type: Electric Pump for creating a vacuum.

Function: It provides a stable vacuum for systems that require a vacuum source (such as brake assist or certain engine control systems).

Features: In modern engines, traditional vacuum sources may be insufficient due to the use of turbocharging and direct injection, so the electric vacuum pump provides the necessary vacuum.

Commonalities:

Driving Method: All electric pumps are driven by electric motors and controlled by an ECU.

Function: They all serve to transfer fluids or provide power within the vehicle system to meet specific functional needs.

Efficiency and Reliability: All require high efficiency, high reliability, and the ability to work stably across the entire operating temperature range of the vehicle.

Differences:

Fluid Type: Each pump is designed to transport different fluids, such as fuel, coolant, hydraulic oil, refrigerant, engine oil, and vacuum.

System Role: They play different roles within the vehicle's system, hence their design parameters such as pressure, flow rate, and temperature range vary.

Design Requirements: The design requirements for each pump differ; for example, fuel pumps need to resist corrosion, coolant pumps need to withstand high temperatures, power steering pumps and brake assist pumps require rapid response.

In summary, the design and application of automotive electric pumps reflect the complexity of automotive engineering and attention to detail. Each pump has its specific functions and design requirements to ensure the efficient and safe operation of the vehicle system. The appropriate pump should be selected based on actual needs.

F. Applications of Electric Pumps in Automobiles

Electric pumps are extensively used in various automotive systems, including:

1.Fuel Supply System: Electric fuel pumps transport fuel from the fuel tank to the engine’s fuel injection system, providing a constant fuel pressure to ensure the engine receives the appropriate fuel supply under various operating conditions.

2.Cooling System: Electric water pumps circulate coolant through the engine’s radiator, helping to maintain the engine at optimal operating temperatures.

3.Power Steering System: Electric power steering pumps supply hydraulic pressure to the power steering system, making steering efforts easier for drivers.

4.Braking System: In some vehicles, electric pumps are used in the hydraulic braking system to provide the necessary braking pressure.

5.Air Conditioning System: Electric AC pumps can circulate refrigerant in the air conditioning system, providing a comfortable cabin temperature for passengers.

6.Lubrication System: While most vehicles use mechanical pumps for lubrication, electric pumps can also be used to assist or serve as the primary lubrication system in certain applications.

7. Turbocharging System: Electric pumps can supply additional compressed air in turbocharged or supercharged systems to enhance engine intake efficiency.

G. Considerations for Electric Pumps

System Compatibility: When designing and selecting electric pumps. Ensure they are compatible with other vehicle systems such as the cooling and fuel systems.

Voltage Stability: Ensure that electric pumps operate stably within the vehicle’s voltage range.

Overload Protection: Electric pumps should have overload protection to prevent damage from prolonged overload operation.

Heat Dissipation Design: High-power electric pumps require a heat dissipation design to prevent overheating.

Electromagnetic Compatibility: Consider the electromagnetic compatibility of electric pumps to avoid interference with other vehicle electronics.

Environmental Adaptability: Electric pumps must adapt to various environmental conditions that vehicles may encounter, such as temperature and humidity.

Regular Inspection: Despite being low-maintenance, electric pumps must adapt to various environmental conditions that vehicles may encounter, such as temperature and humidity.

Electric pumps represent a significant leap in automotive technology and embody a commitment to sustainable development. As technology advances, we anticipate an even broader and more in-depth application of electric pumps in future vehicles.

For any inquiries or needs regarding the production of electric pumps, assembly lines, or equipment, we look forward to engaging in in-depth communication with you at your convenience. Please feel free to contact HONEST at any time:

Tel/Wechat/WhatsApp: +8618923732990

E-mail: sales@cnhonest.com

Related News