News Center

Good News: HONEST Automation’s Flat Wire Motor Stator Twisting Machine Achieves a Technological Breakthrough in Industrial Manufacturing Automation and Intelligence

Published on.

2024-07-15 14:45

Source

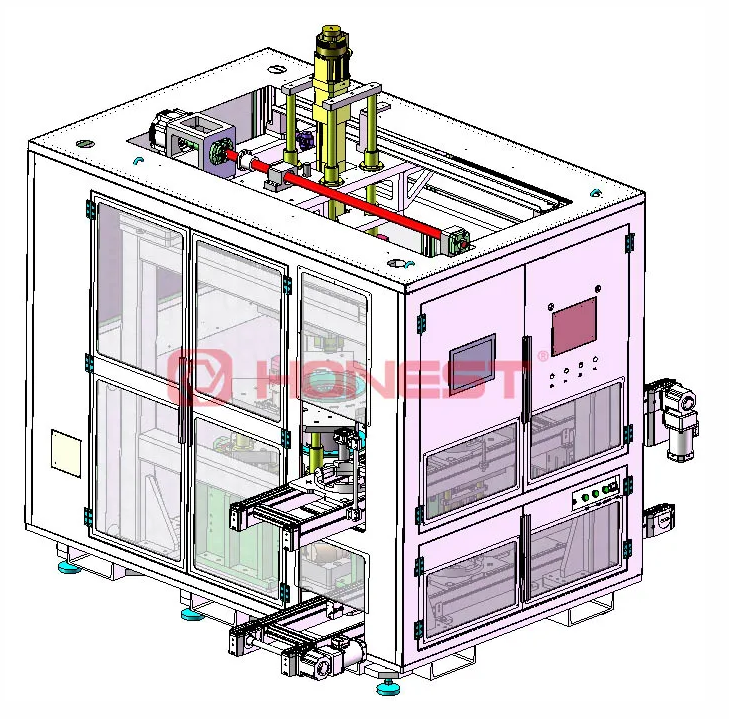

The flat wire motor stator twisting machine, as a key piece of equipment in the production process, plays a crucial role in the precise twisting of the stator winding of flat wire motors. The process directly affects the correct connection of the motor winding, electrical performance, and the smooth progress of subsequent welding. Through in-depth research and breakthroughs in this technology, HONEST Automation has demonstrated its strong capabilities in the field of industrial automation and intelligence.

In terms of the process flow:

1.The equipment uses advanced stop positioning technology and a lifting mechanism to ensure that the stator tray accurately reaches the designated position.

2.The upper and lower needle plates, by using cylinder clamps to hold the product and transport it to the twisting position, automatically protect the paper, achieving efficient processing of the product.

3.During the twisting process, the twisting mold enters the twisting end and rotates, using a two-layer twisting method, which avoids interference with the outer mold of the twisting rod and facilitates the adjustment of twisting parameters.

4.After twisting, the equipment transfers the winding product back to the tray and into the next workstation for subsequent processing, while the twisting mold also resets to its original position, preparing for the next twisting operation.

HONEST Automation, through continuous independent research and development and the breakthrough of technical barriers, not only achieves common production of X-pin and H-pin in the production of the new generation of flat wire motor stator twisting machines; the no-flattening process also reduces equipment investment, thereby saving customers a lot of costs and significantly improving product production efficiency.

When changing the product model, simply replace the upper and lower needle plates, stator clamps, twisting molds, and other tooling modules without the need for secondary manual adjustment. In addition, the equipment also has a high degree of compatibility, whether it is the size of the stator outer diameter or the change in the number of slots, just replace the twisting tooling module, and the mold replacement time is only 5 minutes; this not only reduces the production preparation time but also improves the flexibility and response speed of the entire production line.

The twisting mechanism of the flat wire motor stator is compatible with angles up to about 0-30 degrees, a design that not only solves the angle of cross-slot twisting but also improves the quality and reliability of the product.

The successful development and application of HONEST Automation’s flat wire motor stator twisting machine provide strong support for the evolution of flat wire motor technology. Through automated and intelligent production methods, this equipment not only reduces labor costs for enterprises, improves production efficiency and product quality, but also injects new vitality into the sustainable development of the new energy automotive motor manufacturing industry.

In the future, HONEST Automation will also continue to insist on technological innovation, to empower the industry’s upgrade and development with more advanced automation, intelligence technology, and more stable intelligent equipment solutions.

If you want to know more detailed information, please feel free to contact us at your convenience.

Related News