News Center

E-mobility Hairpin Motor Stator and Powertrain Assembly Line

Published on.

2023-04-27 10:20

Source

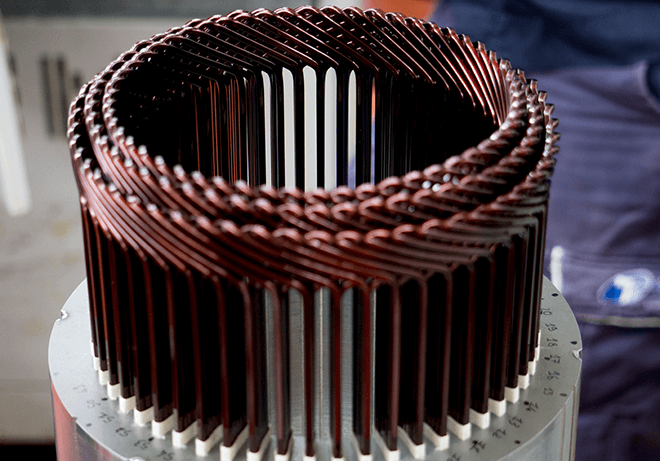

Hairpin motor stator is a type of electric motor stator that has been gaining popularity in recent years due to its unique design and superior performance characteristics. In this article, we will discuss what a hairpin motor stator is, how it works, and its advantages over other types of stators.

What is a Hairpin Motor Stator?

A hairpin motor stator is a type of stator used in electric motors that consists of a series of hairpin-shaped copper or aluminum wires that are bent and twisted to form a compact, efficient winding. Unlike traditional round wire windings, which require separate end-turns to connect the winding to the power source, hairpin windings have an integrated end-turn, which eliminates the need for separate end-turns.

How Does a Hairpin Motor Stator Work?

The operation of a hairpin motor stator is similar to that of a traditional stator. The stator is a stationary component of an electric motor that surrounds the rotor and produces a rotating magnetic field when an electrical current is applied. The magnetic field produced by the stator interacts with the magnetic field produced by the rotor, causing the rotor to rotate.

The unique design of the hairpin motor stator allows for a more efficient and compact winding than traditional stators. The hairpin-shaped wires are twisted together and then inserted into the stator slots, creating a compact, high-density winding that maximizes the amount of copper or aluminum used in the stator.

Advantages of Hairpin Motor Stators

Hairpin motor stators offer several advantages over traditional stators, including:

Higher Efficiency: The compact design of the hairpin motor stator reduces the resistance of the winding, which results in higher efficiency and lower energy consumption.

Higher Power Density: The hairpin motor stator allows for a higher power density than traditional stators, meaning that a smaller motor can produce the same amount of power as a larger motor with a traditional stator.

Improved Thermal Performance: The hairpin motor stator has improved thermal performance compared to traditional stators due to its compact design, which allows for better heat dissipation.

Lower Cost: The hairpin motor stator can be manufactured using less copper or aluminum than traditional stators, which reduces the cost of the stator.

Hairpin motor stators are a relatively new type of stator that offer several advantages over traditional stators, including higher efficiency, higher power density, improved thermal performance, and lower cost. As the demand for more efficient and compact electric motors continues to grow, it is likely that hairpin motor stators will become increasingly popular in a wide range of applications.

An automobile powertrain assembly is a complex system that includes all of the components necessary to convert the power generated by an engine into motion that can be used to propel a vehicle. In this article, we will discuss the components of an automobile powertrain assembly, how it works, and its importance in the operation of a vehicle.

Components of an Automobile Powertrain Assembly

The powertrain assembly of a vehicle typically includes the engine, transmission, driveshaft, differential, and axles. The engine is the primary source of power, generating torque and horsepower that is transmitted to the transmission. The transmission then controls the speed and direction of the power flow and sends it to the driveshaft. The driveshaft is responsible for transferring power to the differential, which then distributes the power to the wheels through the axles.

How an Automobile Powertrain Assembly Works

The powertrain assembly of a vehicle is a complex system that requires the coordination and cooperation of all its components to function properly. The engine generates power that is transferred to the transmission, which then adjusts the speed and direction of the power flow to the driveshaft. The driveshaft then delivers the power to the differential, which distributes it to the wheels through the axles. All of these components work together to convert the power generated by the engine into motion that propels the vehicle forward.

Importance of an Automobile Powertrain Assembly

The powertrain assembly is one of the most important systems in a vehicle, as it is responsible for converting the power generated by the engine into motion that can be used to propel the vehicle. Without a properly functioning powertrain assembly, a vehicle would not be able to move. Additionally, the powertrain assembly is responsible for determining the speed and efficiency of the vehicle. A well-designed powertrain assembly can improve fuel economy and reduce emissions, while a poorly designed one can lead to decreased performance and increased operating costs.

The powertrain assembly of a vehicle is a complex system that includes all of the components necessary to convert the power generated by an engine into motion that can be used to propel a vehicle. The components of a powertrain assembly work together to determine the speed and efficiency of a vehicle, making it an essential part of any automobile. As the demand for more efficient and environmentally-friendly vehicles continues to grow, it is likely that the design and function of powertrain assemblies will continue to evolve to meet these demands.

Advantages of HONEST Automation hairpin motor stator and powertrain assembly equipment

HONEST Automation has more than 16 years of experience in the field of motor automation assembly and is currently able to provide fully automatic and semi-automatic E-mobility hairpin motor stator and rotor assembly line, automobile powertrain assembly line, new energy drive motor assembly equipment.

The equipment can automatically start the slotted paper, the marks of different products are different, the tool replacement can be used repeatedly, and manual refueling does not need to stop. Support 48 slots, 54 slots and 72 slots.

The cutting station will not produce waste wire, any type of copper wire is compatible, the cut is flat, it can be directly welded, and the length is consistent. 3D molding can automatically change multiple sets of molds, and supports multiple line types at one time.

It has the function of storing wires, and a single defective wire can be called directly from the storage wire, with a high yield rate.

Related News