News Center

The Motor Manufacturing Industry Breaks Through Traditional Production Methods to Meet New Opportunities

Published on.

2025-01-21 16:30

Source

Traditional production and manufacturing methods have gradually revealed some drawbacks in the tide of the times. For example, manual operation has high uncertainty, and different workers have different technical levels and operating habits, which makes it difficult to maintain a high degree of consistency in product quality. This seriously affects the company's brand image and market reputation. For another example, manual labor is relatively low in production efficiency and is often unable to meet the needs of large-scale production. Low production efficiency increases the company's production costs and weakens the company's competitiveness in the market. At the same time, the limitations of manual inspection are also more obvious. After working for a long time, inspectors are prone to fatigue, resulting in missed inspections, false inspections, etc. Allowing unqualified products to enter the market may bring legal risks and economic compensation to the company.

Faced with the difficulties of traditional manufacturing, HONEST motor automation production has become the mainstream trend in the industry. Compared with the traditional manufacturing model, the motor assembly line has injected new vitality into the industry development with its many advantages such as high efficiency and precision. The motor assembly line has taken a series of effective measures in the process of ensuring production quality control:

1. Layered quality control of the production process: clearly divide the levels of raw material procurement, production, assembly, and inspection, and formulate corresponding quality inspection and control measures for each level.

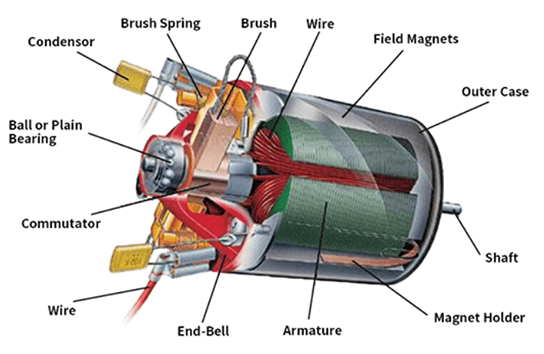

2. Understand the working principle of the product motor: Knowing the working principle of the product is the basis of quality control and helps to determine key quality control points and testing technologies.

3. Apply scientific management concepts: use modern advanced computer technology, information technology and data analysis technology to control and improve the quality of the production process. Through data analysis, potential quality control problems can be predicted in advance, and corresponding measures can be taken to solve them.

4. Inspection and monitoring: The motor production line is equipped with advanced testing equipment to automate the testing process. This not only greatly reduces the reliance on inspectors and monitors, and reduces labor costs, but also improves the accuracy and efficiency of testing, avoiding possible omissions in manual testing.

5. Controlled state of the production process: Comprehensive analysis, diagnosis and monitoring of the production, installation and service processes that directly or indirectly affect product quality. Once an abnormal situation is found, adjustments can be made quickly to ensure the stability of production and the reliability of product quality.

6. Regularly evaluate and review the quality management system: Make continuous improvements based on feedback and data, and continuously optimize production processes and quality control measures so that the quality control level of the motor assembly line can keep pace with the times and adapt to the changing market demands and technological development trends.

Quality control in the HONEST motor production line runs through the entire production process and is an overall management task. By comprehensively applying the above-mentioned measures, the quality and safety of motor products can be effectively ensured, helping motor manufacturers to stand out in the fierce market competition and achieve sustainable development.

Related News