News Center

Why Electric Motors Dominate Humanoid Robotics

Published on.

2025-06-18 11:00

Source

In today’s era of rapid technological advancement, humanoid robots—an integration of artificial intelligence, mechanical engineering, and automation—are emerging as a key force in driving the intelligent transformation of society. From industrial manufacturing to social services, their application scenarios are expanding rapidly. Among the many core technologies, electric motor drive systems have become the most mainstream choice for humanoid robots due to their high energy efficiency, controllability, and flexibility.

Why Electric Motor Drives?

As global populations age, labor costs continue to rise, and the demand for intelligent manufacturing accelerates, humanoid robots are increasingly viewed as a critical solution to future societal challenges. These robots are capable of handling highly repetitive or hazardous tasks while also enabling more natural interaction with humans, boosting both productivity and service quality.

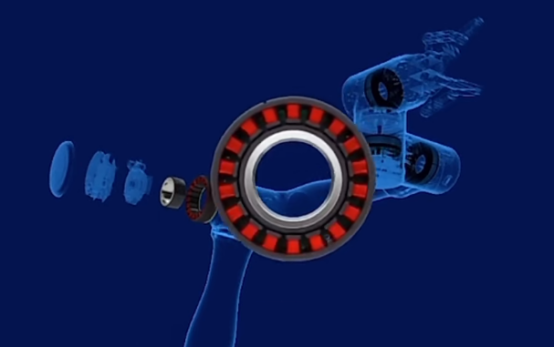

In the design of humanoid robots, achieving precise motion control, high flexibility, and fast responsiveness presents a major technical hurdle. Electric motors, with their mature industrial foundation, excellent controllability, and efficient energy conversion, have become the dominant drive choice. Whether powering bionic arms, leg joints, or head rotation, motors offer smooth and accurate torque output, ensuring the execution of complex, coordinated movements.

What Makes Electric Motor Drives Ideal for Humanoid Robots?

Precision Control and Fast Response

Compared to other actuation methods, electric motors offer outstanding speed control and positioning accuracy. Brushless DC motors (BLDC) and permanent magnet synchronous motors (PMSM) in particular are known for their rapid response and smooth torque delivery, making them ideal for humanoid robots that require frequent motion transitions and high-precision operation.

High Energy Efficiency and Extended Battery Life

Compared to hydraulic or pneumatic systems, electric motors offer significantly higher energy conversion efficiency. They perform especially well under low-load conditions, helping to reduce overall energy consumption and extend the operating time of humanoid robots.

Enhanced Safety and Reliability

Unlike systems that rely on high-pressure fluids or gases, electric motor drives eliminate the risk of leaks, explosions, or hazardous emissions, making them a safer and more reliable option for both indoor and outdoor robotic applications.

Adaptability Across Various Tasks and Environments

With a wide range of motor types and control strategies available, electric drive systems can be easily tuned to meet different torque, speed, and precision requirements, allowing humanoid robots to operate effectively in diverse industrial, service, or research settings.

Electric Motors Simplify Assembly and System Integration

Modular Design Compatibility

Modern humanoid robots are typically built on a modular design framework. Electric motor drives are inherently suited for this approach, as each joint or actuator can be packaged as a self-contained module. These modules often include the servo motor, gearbox, encoder, and controller, allowing for plug-and-play flexibility in assembly and maintenance.

Mature and Standardized Supply Chain

Electric motors and their supporting components are backed by a highly standardized industrial supply chain. This ensures high manufacturing precision, strong product consistency, and scalability for mass production. As a result, manufacturers benefit from reduced calibration effort, lower failure rates, and improved production efficiency.

Easy Integration with Embedded Control and Sensor Systems

Electric motor systems can be seamlessly integrated with embedded control platforms and sensor networks. This enables real-time closed-loop feedback, enhancing motion control accuracy and overall system responsiveness in humanoid robots.

It is evident that electric motor drives have become the mainstream choice for humanoid robots due to their unmatched advantages in both production and performance. During the assembly phase, motors offer modularity, standardization, and consistency—facilitating efficient and scalable manufacturing. In real-world operation, they provide high-precision control, superior energy efficiency, and enhanced safety, making them ideal for the complex and dynamic demands of humanoid robotics.

As a trusted provider of motor automation equipment, HONEST Automation leverages years of experience in motor assembly line development and technical innovation. From solution design and equipment manufacturing to on-site commissioning and after-sales service, we deliver one-stop, customized production solutions tailored to the needs of humanoid robot motor drive systems.

If you're exploring production solutions for humanoid robot motor drives, we warmly invite you to visit our factory and see our advanced automation capabilities firsthand. We look forward to working with you to advance the future of intelligent robotics.

Related News