News Center

How Can Motor Production Lines Be Compatible With Different Specifications of Inner Rotor Motors

Published on.

2025-09-12 14:01

Source

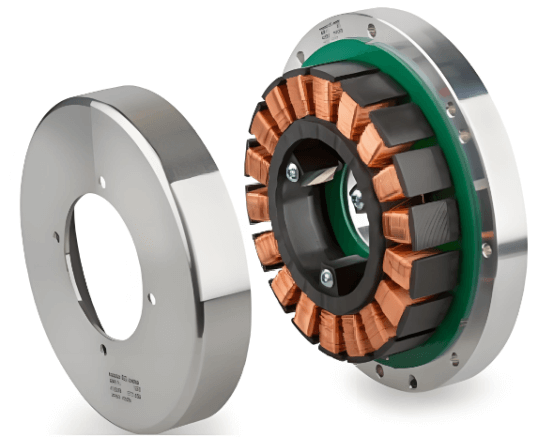

Driven by the rapid growth of new energy vehicles, smart homes, and industrial automation, motors as core power units are experiencing diversified development. Among them, inner rotor motors stand out for their compact structure, high efficiency, and fast response, making them widely used in power tools, drones, robots, and household appliances.

However, this market prosperity also brings new challenges: motor product demand is shifting toward a trend of “multiple varieties, small batches, and short delivery cycles.” A single motor manufacturer may receive dozens of orders with different specifications, such as power density, motor outer diameter, pole pair number, winding method, shaft length, and end cap structure. Building a dedicated automated production line for each model would not only require significant equipment investment and extensive floor space but also lead to issues such as idle lines, difficult changeovers, and prolonged return on investment cycles.

Against this backdrop, building an automated assembly line that can flexibly accommodate multiple specifications of inner rotor motors has become a crucial breakthrough for enterprises to reduce costs, improve efficiency, and enhance competitiveness.

1. Traditional Automated Production Lines: Rigidity vs. Flexibility

Conventional motor production line typically follow a “rigid design,” where the line structure, tooling fixtures, motion paths, and cycle parameters are all optimized for a single specific model. Once the product changes, manufacturers often need to replace the entire set of customized fixtures, reprogram robotic paths, adjust conveyor height and pitch, or even shut down production for days to modify the line.

This “stop production for changeover” model has become a major bottleneck in today’s environment of frequent small-batch, multi-variety orders. At the same time, the high equipment costs and low line utilization rates place motor manufacturers in a dilemma—struggling with both unaffordable investments and underperforming production output.

2. Flexible Compatibility: Supported by Four Core Technologies

Enabling a production line to handle multiple specifications of inner rotor motors relies on two fundamentals: flexible design and intelligent control. Modern automated production lines address this challenge through four core technologies, which provide strong support for motor manufacturing.

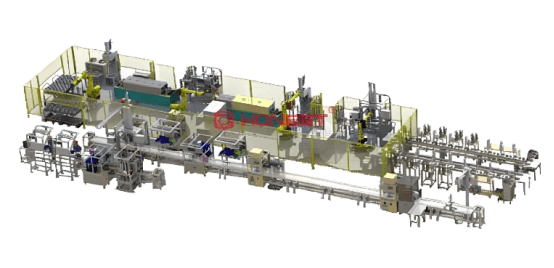

Modular Design: Modern flexible production lines adopt a modular architecture, breaking down traditional assembly processes—such as loading, stator winding insertion, rotor assembly, shaft pressing, welding, testing, and unloading—into independent functional units. Each module can be upgraded or replaced individually, allowing manufacturers to adapt to different motor models simply by adjusting or swapping the relevant modules, without the need to rebuild the entire line.

One Fixture for Multiple Sizes: By integrating technologies such as electrically/pneumatically adjustable clamps, servo-driven slides, and floating positioning mechanisms, the tooling can achieve rapid changeover and adaptive adjustment.

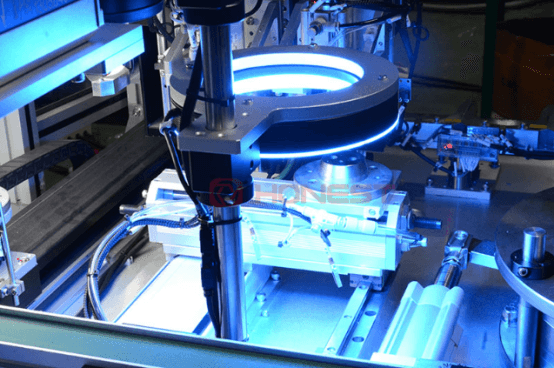

Digital Twin and Intelligent Control System: By integrating the MES (Manufacturing Execution System) with the PLC (Programmable Logic Controller), each motor is automatically identified via a QR code or RFID when it enters the line. The system then retrieves the corresponding process parameter package, which includes robotic motion paths, pressing force and stroke, winding parameters (such as turns and angles), and testing standards (such as no-load current and back-EMF). This “one code drives the entire process” approach significantly improves both changeover efficiency and accuracy.

High-Precision Vision and Force Control Technology: To address subtle differences among various motor models, 2D/3D vision systems are employed for positioning and correction, ensuring assembly accuracy. At the same time, force control technology is applied in critical processes—such as shaft pressing and pin insertion—to monitor contact force in real time, preventing damage caused by dimensional tolerances and thereby improving yield rates.

A flexible automated production line with multi-model compatibility can deliver significant value to enterprises, such as reducing equipment investment, shortening changeover time, enhancing delivery capability, and enabling easier future expansion.

Under the wave of smart manufacturing, automated production lines are no longer just about “replacing manual labor with machines,” but are evolving toward flexibility, intelligence, and digitalization. For inner rotor motor manufacturing, a flexible production line capable of handling multiple models is not only a powerful tool to meet rapidly changing market demands but also a “new infrastructure” for achieving lean production and strengthening core competitiveness.

As a solution provider with 18 years of expertise in intelligent motor equipment, Honest Automation is dedicated to delivering flexible and customized automated motor assembly solutions for global customers. Since its establishment in 2007, the company has successfully delivered more than 1,000 customized automation production lines, serving over 100 customers worldwide. Its smart manufacturing solutions cover a wide range of industries, including new energy vehicles, rail transit, automotive electric components, humanoid robots, low-altitude aircraft, household appliances, and industrial applications.

If you are looking for a flexible and intelligent upgrade path, Honest Automation is ready to be your trusted partner. Whether it is rapid changeovers for small-batch, multi-model production or advanced production lines for new energy flat-wire motors, we provide full lifecycle support—from solution design and R&D to manufacturing and delivery.

Contact us online to receive your customized solution. Let Honest Automation make your production easier, more efficient, and more competitive.

Related News