News Center

How Important Is Humanoid Robot Motor Performance Testing?

Published on.

2025-10-18 16:54

Source

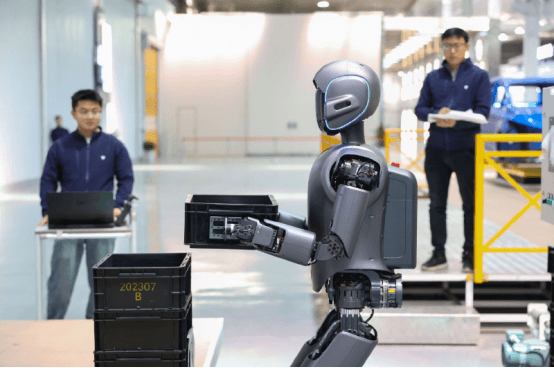

As humanoid robots enter factories to perform inspection, delivery, and assistance tasks, the focus has shifted from simply asking “Can it move?” to “Can it walk steadily?”, “Are its movements precise?”, and “Can it operate continuously without vibration?”

In other words, humanoid robots are no longer just moving machines—they are intelligent systems that must maintain high stability and precision in real industrial environments.

Behind this lies the demand for higher reliability and consistency across the entire humanoid robot system.

Among all the factors, joint motor performance testing plays a pivotal role.

In the world of robotics, “installing a motor” does not necessarily mean “the motor is ready.”

The real challenge is not about making the robot move—it’s about ensuring it moves steadily, precisely, and durably.

A humanoid robot typically features 20 to 40 high-dynamic joints, each powered by a precision servo motor at its core.

These motors must deliver not only stable torque but also fast response, low vibration, and precise feedback, ensuring smooth and coordinated motion during complex robotic operations.

If any performance parameter falls below standard, it can trigger a series of chain reactions:

uneven torque output may cause unstable gait or even falls during walking;

Excessive vibration can lead to higher noise, shorter lifespan, and interference with IMU sensors that detect posture;

and delayed or inaccurate feedback signals can result in sluggish movements and poor arm coordination, ultimately reducing task accuracy and operational efficiency.

In motor performance testing, even the slightest deviation can make the difference between usable and unusable.

During the prototype or small-batch phase, many companies still rely on manual testing—operators connect wires by hand, read data from oscilloscopes, and record results manually.

While this may seem workable at first, it is highly experience-dependent and unsustainable in the long run. Once production scales up, three critical weaknesses quickly emerge:

1. Lack of precision: Manual testing cannot accurately detect subtle vibration frequencies or torque fluctuations. Results depend heavily on the operator’s skill and condition, leading to poor product consistency and frequent misjudgments.

2. Low efficiency and limited coverage: Each test typically takes 15–30 minutes. When production reaches thousands of units per month, full inspection becomes impossible. Most companies resort to sampling tests, leaving a high risk of undetected defects.

3. Poor data traceability: Test results are often recorded by hand or in spreadsheets, with inconsistent formats, frequent errors, and limited traceability. When a batch-quality issue arises, it becomes nearly impossible to identify which production stage or batch caused the problem quickly.

Manual testing may allow a robot to have a motor installed, but it cannot ensure the motor is truly ready for operation.

To achieve mass production of humanoid robots while maintaining consistent performance testing, companies must rely on automated, high-precision, and fully traceable performance testing systems.

These systems serve not only as quality verification tools but also as the “gatekeepers” of scalable production.

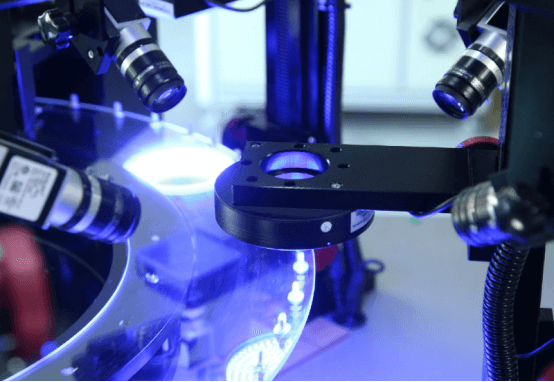

High-Precision Sensors + Intelligent Algorithms for Comprehensive Performance Evaluation

By integrating high-precision torque sensors, encoder analyzers, and professional software algorithms, these systems automatically collect and analyze every motor’s parameters, accurately determining pass/fail status and completely eliminating the risk of human error.

Fully Automated Workflow for Double Efficiency

With robots or vibratory feeders handling loading and unloading, automated wiring fixtures, and one-touch test initiation, the entire testing process requires no manual intervention.

Test cycles can be completed in 3–5 minutes per unit, supporting 100% full inspection and significantly improving production efficiency.

Closed-Loop Data System for Full Traceability and Optimization

Each motor automatically generates a unique digital profile containing all raw test data and results, enabling quick traceability and rapid identification of problematic batches.

Through Statistical Process Control (SPC), key parameters are monitored in real time, providing early warnings of process deviations.

Additionally, integration with Manufacturing Execution Systems (MES) allows seamless communication with production management, laying the foundation for smart manufacturing.

Flexible Design for Multi-Model Production Lines

With modular tooling and a configurable software platform, the system supports mixed-line production of motors with varying power, interfaces, and testing standards. Quick changeovers make it ideal for the small-batch, multi-model R&D and production requirements of humanoid robots.

To meet the extreme demands for precision and consistency in humanoid robotics, Honest Automation leverages 18 years of experience in intelligent motor equipment to provide integrated assembly and testing modular workstations for electric vehicles, rail transportation, humanoid robots, and low-altitude aircraft.

Customized test rigs and software logic are designed according to client-specific key structures, interface types, and testing standards, ensuring solutions are fully aligned with production line requirements and making non-standard customization more efficient and precise.

The competitiveness of humanoid robots lies not only in their intelligence but also in their reliability.

This reliability starts with the precise assembly and rigorous testing of every joint motor.

In essence, assembly sets the lower bound of performance, while testing determines its upper limit.

Only through automated, full-parameter, and traceable performance verification can the transition from prototype to mass-produced humanoid robots be truly achieved.

Leveraging its deep understanding of motor performance, Honest Automation provides humanoid robot manufacturers with high-precision, high-efficiency, and highly consistent automated assembly and testing support, helping clients create more stable and reliable intelligent joints.

Suppose you are planning solutions for a humanoid robot motor assembly line or complete humanoid robot assembly, or seeking to improve assembly consistency and product yield. In that case, we invite you to visit Honest Automation. We look forward to engaging with you and embracing the era of humanoid robot mass production together.

Related News