Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

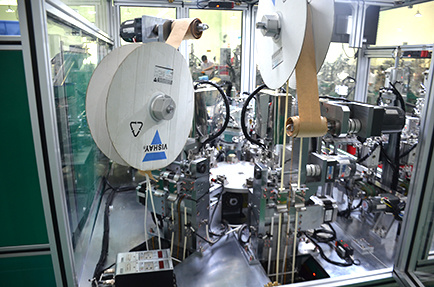

Sweeping robots motor end cap assembly line

Sweeping robots motor end cap assembly line includes automatic loading, positioning, bearing assembly, pressing rivet (with pressure feedback), soldering tin, brush forming, inserting carbon crystal into the brush holder, shockproof adhesive, brush insertion, riveting, capacitor assembly, appearance inspection and other processes (customized according to the customer’s process)

ONLINE CONSULTATIONproduct details

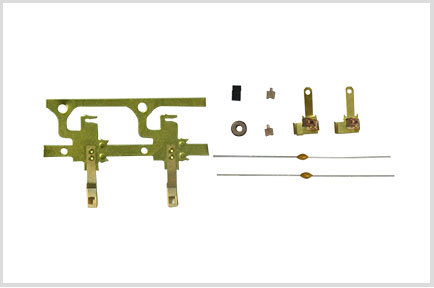

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

The equipment transports material in a straight line

-

02

Asemble Carbon crystal and brush holder

-

03

The electric box adopts imported door magnetic switch with high safety factor

-

04

Reasonable human-computer interface, convenient to operate and stable equipment

-

05

Adopt Gaozhoubo welder to make the surface smooth.

-

06

Fully automatic production

Equipment parameters

-

Scope of application

-

Motor end cap assembly

-

Loading mode

-

Fully automatic

-

Inloading mode

-

Automatic collection by plate

-

Power

-

7.5kw

-

Gas pressure

-

0.4~0.6MPa

-

Power supply

-

AC 220V 50Hz

Recommended Products