Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

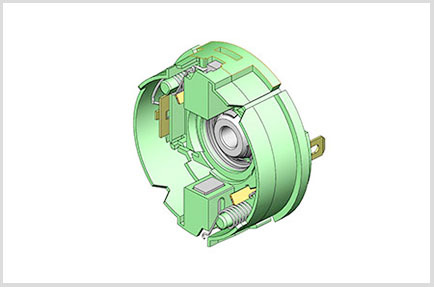

DC Motor End Cap Production Line

DC motor end cap production line adopts a modular design, has good compatibility, is compatible with 23 products, and has an efficiency of 3s per pcs. The rapid conversion is realized by replacing the shipboard, adjusting the replacement blade and replacing the special parts, and is equipped with a visual inspection system to realize stable and efficient product inspection and improve production efficiency. The main completion processes include automatic feeding, plugs, connectors, capacitors, connection, inductance, wiring, welding, testing and blanking, etc.

ONLINE CONSULTATIONproduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Modular design, good compatibility

-

02

With the function of identifying fixtures, the alarm will prompt when there is an error in the treatment

-

03

Eight stations soldering, soldering parameters can be adjusted and controlled

-

04

Compatible with 23 products, the efficiency is 3s per pcs

-

05

The visual system is used to detect capacitance and terminal connection lines, which is efficient in detection and stable in results

-

06

Automatic swing plate blanking, long blanking cycle time

Equipment parameters

-

Efficiency

-

3s per PCS

-

Conversion time

-

30min

-

Voltage

-

AC220V/380V 50HZ

-

Air pressure

-

0.4~0.6MPa

-

Physical dimension

-

9.5(L)*2.22(W)*1.8(H)m

-

Control method

-

PLC + touch screen

-

Power

-

20KW

-

Pass rate

-

≥99%

Recommended Products