Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Automobile Air Conditioning Motor Production Line

Motor production line used in automobile air-conditioning air distribution system. This line consists of three parts: rotor assembly line, magnetic bottom assembly line, and motor group assembly line. It can compatible with 19 types of assembly lines, modular and flexible design, making the application more flexible. It has a wide range of product compatibility so that it can save the cost for changing types and it also can solve the problem of labor cost, technology, management, and other problems.

ONLINE CONSULTATIONproduct details

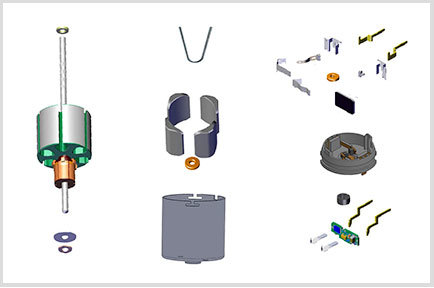

Split-graph

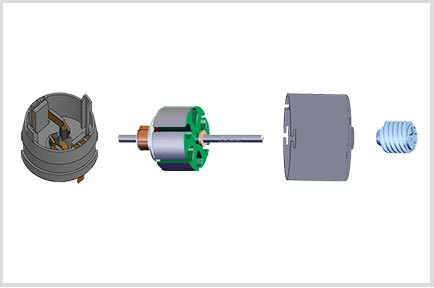

Finished-product-drawing

Local graph

Advantages

-

01

Compatible with 19 types of production, it can be changed type fastly by HMI program and tool.

-

02

Softy bin loading system can reduce worm scrap and the type changing time.

-

03

Commutator spot welding, configure industrial computer for data tracing, and collect welding power monitoring data.

-

04

Configured face recognition access control to prevent the loss or injury made by the non-technical specialist

-

05

Highly efficient assembly and gluing of 4 pieces of magnets at one time

-

06

Configured high-precision and visual detection system to check the existence of units and quality inspection of the final product.

Equipment parameters

-

Production efficiency

-

≤3.2s/pcs

-

Compatible product

-

19

-

Type changing time

-

No more than 30 min

-

Power supply

-

Main incoming line Three-phase AC380V 50HZ

-

Gas pressure

-

0.45-0.65MPa

-

Yield

-

≥99%

-

Utilization rate

-

All line ≥90%

-

Power

-

100KW

-

Application area

-

automobile air-conditioning air distribution system & Damper motor

-

Dimension

-

35.5(L)*4.5(W)*2(H)m

Recommended Products