Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

Automotive fan motor assembly line

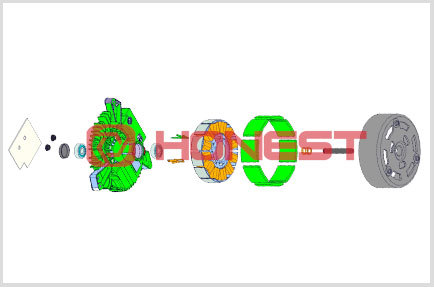

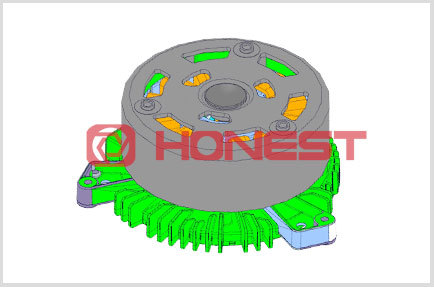

High automatic assembly line with good quality, it contains rotor dynamic balance testing, rotor magnetizing, teminal assembly and winding, stator installation, bearing cover assembly, PCBA assembly, back cover pressing, motor performance testing, etc. The automotive fan motor assembly line makes full use of technical methods such as power traceability, visual inspection, depth inspection, upward material identification, mixed material identification, missing packaging identification, positive side identification of material assembly, pressure monitoring, etc. to achieve the effect of fool-proof and error-proof, and the error-proof rate It can reach 100%, and the entire production line is integrated with MES to realize the full traceability of product production process information.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Configured with high precision sensor, visual testing system,etc

-

02

The device prompts various wrong operations and bad states in real time

-

03

The equipment conforms to the ergonomic design, and the operation is simple and easy to use

-

04

The equipment has the function of door opening and air pressure safety protection

-

05

The equipment has the function of assembly lack, wrong flow, equality after assmebly inspection

-

06

The monitor alarm on touch screen when the equipment is abnormal. It is convenient to operate.

Equipment parameters

-

Efficiency

-

10.6s /pcs

-

Compatible product

-

2 types

-

Exchange time

-

No more than 10Min

-

Pass rate

-

More than 99.9%

-

Full-day time utilization

-

More than 90%

-

Air pressure

- 0.3~0.8Mpa

-

Voltage

-

AC220V 50HZ

-

Power

-

The whole line is about 15KW

-

Control method

-

PLC + touch screen

-

Physical dimension

-

1000(L)*3100(W)*2000(H)mm

Recommended Products