Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

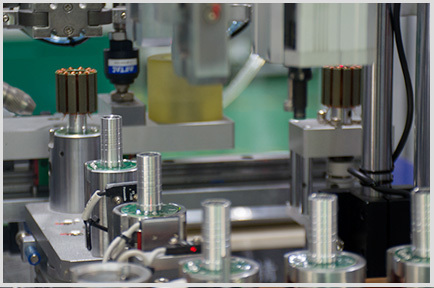

Vacuum cleaner brushless motor production equipment

Brushless motor production equipment is used in the production of household motors. Compared with the original production line, the equipment saves 32 manpower and improves the efficiency by 3 to 4 times. Its crafts include: 1. Base section: circuit board installation, finale, gluing, drying, etc. 2. Rotor section: gluing, shell pressing, magnet loading, final shaft, etc. 3. Assembly section: loading, assembling, gluing, drying, testing and other processes are completed.

ONLINE CONSULTATIONProduct details

Split-graph

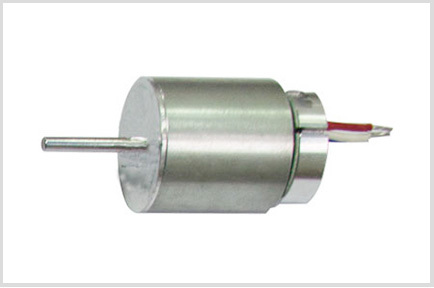

Finished-product-drawing

Local graph

Advantages

-

01

The magnet assembly is equipped with inner diameter and missing assembly detection, and the defective is automatically discharged.

-

02

Glue curing has a heating wire disconnection detection and alarm function.

-

03

Compared with the original production line: saving 32 manpower and increasing efficiency by 3 to 4 times.

-

04

Rotor dual position dynamic balance detection.

-

05

The components are all high-end mainstream brands, with high quality assurance and durability.

-

06

The shaft is pressed into the rotor and equipped with a high-precision dispensing machine to control the amount of dispensing and refueling.

Equipment parameters

-

Efficiency

-

5S/PCS

-

Pass rate

-

≥98% (except for factors such as poor incoming materials or manual debugging)

-

Feeding method

-

Automatic grabbing and loading by the manipulator.

-

Discharge method

-

Robot unloading

-

Power supply

-

AC220V/380V 50HZ

-

Atmospheric pressure

- 0.4-0.6MPa

-

Physical dimension

-

22(L)*1.3(W)*1.8(H)m

Recommended Products