Products

Customized solutions for motor production lines

18-YEAR MATANLESS CRAFTSMANSHIP

Intelligent

Flexible

Digital

Networked

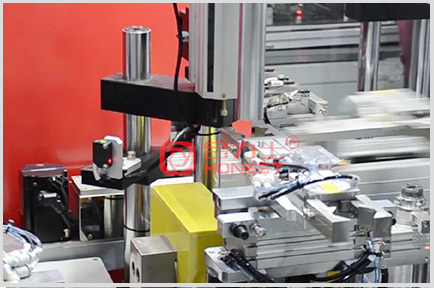

Automobile Window Lifter Motor Production Line

This line is used in the production line of the automobile window lifter motor. The process includes rotor section: rotor automatic feeding, winding, spot welding, finishing turning, etc. The stator section includes: bearing press-fitting, magnetic tile & slingshot assembly, magnetization, etc. The end cover section includes: bearing press-fitting, carbon crystal & brush arm assembly, brush assembly, end cover soldering, etc. The motor assembly section includes rotor & end cover & stator automatic feeding, gasket assembly, shaft beading, magnetic ring assembly, worm press assembly, motor assembly process.

ONLINE CONSULTATIONProduct details

Split-graph

Finished-product-drawing

Local graph

Advantages

-

01

Fully automated production.

-

02

More than 900PCS per hour.

-

03

Station flying fork winding.

-

04

Rotor assembly shaft bending core measurement and correction.

-

05

Each part has detection and marking functions.

-

06

Non-standard can be customized.

Equipment parameters

-

Efficiency

-

More than 900psc/h

-

Feeding method

-

Automatic feeding by manipulator.

-

Discharge method

-

Conveyed by the belt

-

Gas source

-

0.5-0.7MPa

-

Power supply

-

AC 380V, 50HZ

Recommended Products