News Center

Vehicle Hairpin Motor Stator Winding Technology

Published on.

2021-07-06 09:11

Source

The development of new energy vehicles is an important strategy for tackling climate change and promoting green development. At present, the global technological revolution and industrial transformation are vigorously developing, and related technologies in the fields of automobile and energy, transportation, information and communication are accelerating integration, electrification, networking, and intelligence have become the development trend of the automobile industry.

New energy vehicles combine new energy, new materials and multiple transformative technologies such as the Internet, big data, artificial intelligence, etc. In recent years, the world's automobile powers have strengthened strategic planning and policy support. Multinational automobile companies have increased R&D investment and improved industrial layout. New energy vehicles have become the main direction of the transformation and development of the global automobile industry and an important engine for the continuous growth of the world economy.

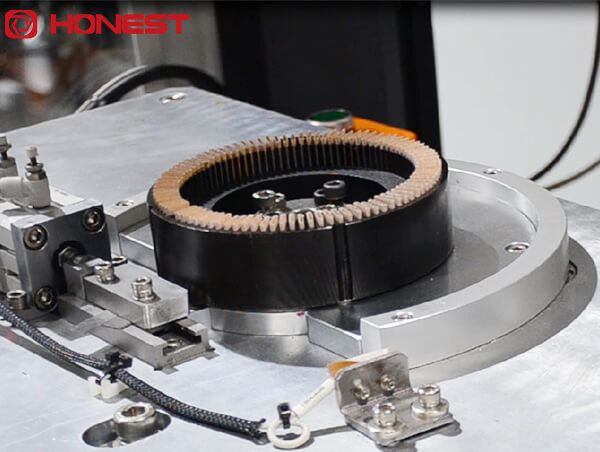

Hairpin motor stator is mainly used in the BSG motor of new energy vehicles, concentrated in the field of starter and generator. Hairpin motor can more easily strengthen the structure of the key connection, and the winding is also suitable for liquid cooling, which further improves the performance and reliability. Research shows that, compared with other motor windings, motors designed and manufactured using hairpin windings have higher efficiency. This is conducive to the efficiency, power density, thermal resistance and performance of the smart sport utility vehicle.

Because the copper wire of the hairpin motor is thicker, the resistance is small, and the energy lost on the heating is less. The winding end size of the hairpin motor is shorter than that of the round wire motor, which reduces the copper loss. It increases the area of the maximum efficiency zone, which means that the car can reach maximum efficiency when driving in urban congestion and on highways. In addition, the hairpin motor can be used in more stator windings, which means that the motor can output higher power and torque with the same energy loss. The flat wire used in the hairpin motor has a more regular shape and reduces the thermal resistance in the stator slot. It provides higher heat transfer efficiency, which further improves peak power and sustained performance. Because of the high rigidity of the hairpin motor, it can provide better heat dissipation capacity and performance, so that the driving has a better experience.

The hairpin winding technology manufacturing process is relatively complicated, the investment cost is quite high, and it hasn't been widely used. The wire needs to be shaped into a hairpin before it can be automatically inserted into the stator core slot, and the end needs to be twisted and welded. Therefore, the hairpin motor can't be manufactured by workers, because the workers don't have enough physical strength to handle the thick copper wire and complete the good regularity. It takes many investments to purchase one automatic hairpin motor assembly line. For some automobile manufacturers, it's worthwhile to invest in the production line of hairpin motors. Because the new energy automobile industry has good consumption potential, there are many consumers, and the value and price of the automobile industry are very high.

HONEST Automation is a new energy vehicle drive motor equipment solution provider. We have developed hairpin motor winding assembly line. The equipment has key components lifespan management, face recognition, and supports real-time tracking of production data to achieve intelligent and efficient production. Equipment advantages include high-speed production and reliability, high stability and intelligence. HONEST can be customized automation equipment solutions according to the customer's hairpin motor and process requirements.

Related News