News Center

Key Issues and Countermeasures of Digital Transformation of Drive Motor Production Line

Published on.

2023-08-18 15:09

Source

With the rapid development of technology, digital transformation has become an important trend in many industrial fields.

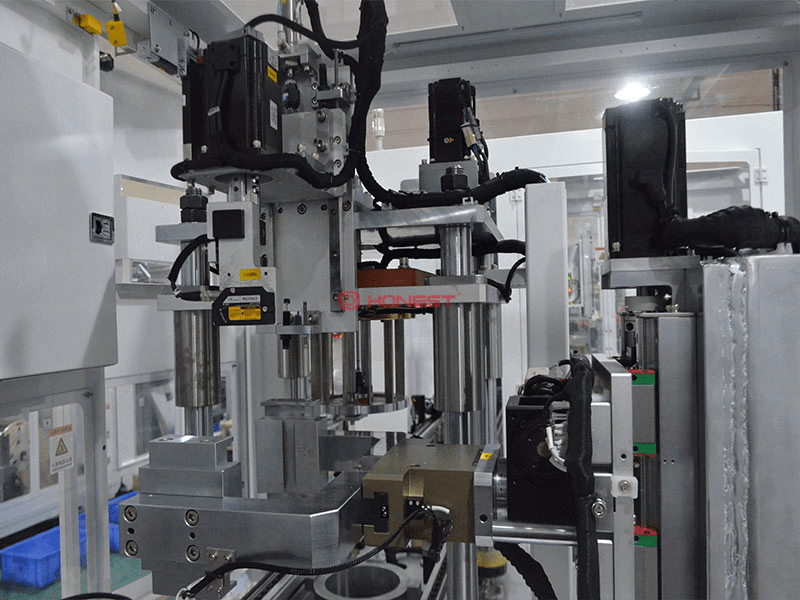

As an important part of machinery manufacturing, its digital transformation is of great significance for improving production efficiency, reducing costs and optimizing product quality. However, there are some key issues in the process of realizing the digital transformation of the drive motor production line. HONEST will analyze these key issues and propose corresponding countermeasures to promote the digitalization process of the drive motor production line.

1. Layout and Device Compatibility

In the traditional drive motor production line, the equipment layout is often designed based on experience, which may lead to an unsmooth production process. In addition, compatibility issues between different devices can also affect production efficiency and product quality. Therefore, solving the problems of production line layout and equipment compatibility has become the primary task of digital transformation.

Countermeasure: Use digital simulation technology to design the layout of the production line. Through 3D simulation software, the actual production process can be simulated in a virtual environment, so as to find out the optimal production line layout. In addition, the information interaction capability between devices should be ensured so as to realize data sharing and collaborative work in the production process.

2. Production Data Management and Analysis

The large amount of data generated during the production of drive motors is of great value for optimizing the production process. However, how to effectively collect, store and analyze this data is a challenge for digital transformation.

Countermeasures: Establish a comprehensive production data management system. The system should be able to collect and integrate data generated by individual devices in real time for analysis and optimization. Through data mining and analysis techniques, we can discover patterns and trends hidden in the data, thus providing strong support for production decisions.

3. Staff Training and Collaborative Work

Digital transformation requires advanced equipment and systems, as well as employees with relevant skills. However, employees working on traditional production lines often lack digital skills, which will be an obstacle to digital transformation.

Countermeasure: Strengthen employee training and improve their digital skills. Through regular training courses and technical exchanges, employees are familiar with and master the operation and maintenance of digital equipment and systems. In addition, establish a collaborative working mechanism to strengthen communication and cooperation between teams to ensure a good production order during the digital transformation process.

4. Information Security and Privacy Protection

In the process of digital transformation, data transmission and processing on the production line has become more frequent. How to ensure information security and privacy protection has become a problem that cannot be ignored.

Countermeasures: Establish a sound safety management system. The system should include security measures such as network firewall, data encryption, and access control to prevent malicious attacks and data leakage. In addition, regular security audits and training are conducted to improve employees' security awareness and skills to ensure information security and privacy protection.

The digital transformation of the drive motor production line improves production efficiency and reduces costs. We should make full use of advanced digital technology and formulate practical countermeasures to promote the digitalization process of the drive motor production line and achieve efficient production.

Related News