News Center

HONEST Brushless Oil Pump Motor Fully Automated Production Line

Published on.

2024-04-10 09:00

Source

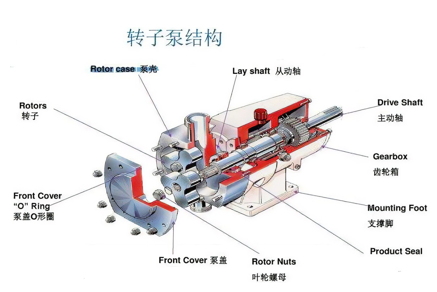

The oil pump is a significant component of an automobile fuel supply system. It increases oil pressure during automobile lubrication, ensures oil is sent to the friction surfaces of the engine, and stores a certain amount of oil within the pump. Its core function is to provide the engine with a stable and sufficient fuel supply.

The performance of the oil pump directly affects the fuel supply and supply pressure of the engine and plays a vital role in the starting, acceleration, and driving stability of the engine.

HONEST Brushless Oil Pump Motor Fully Automated Production Line

The HONEST brushless oil pump motor fully automated production line consists of 19 pieces of equipment. It utilizes a conveyor line and ship plate for a return-type transportation method. The process incorporates data traceability, visual inspection, depth inspection, upward material identification, mixed identification, missing packaging identification, pressure monitoring, and displacement monitoring to ensure a foolproof production process.

The process flow is divided into: stator manufacturing → rotor manufacturing → rotor and stator assembly and testing.

The Equipment Process

Automatic assembly of upper and lower insulation covers →clip welding→assembly of magnetic steel into the core, rotor, and end cover →assembly of signal magnets → locking screws→testing of the motor's back electromotive force, current, speed, and other assembly processes.

The Equipment Advantages

1. The equipment adopts a double clamping jaw design, which changes loading and unloading methods, saving time and improving the working efficiency of the equipment;

2. The winding parameters are controllable, the tension can be adjusted during the winding process, the waste wire can be automatically collected, and the wire diameter compatibility range is 0.5-1.2mm;

3. Equipped with a resistance welding power source, it automatically moves the clamping welding head, clamps the three terminal hooks in sequence, and is equipped with a pressure sensor to monitor the clamping force (the wire diameter deforms by 30%-50% after butt welding);

4. The oil seal is assembled into the casing using a manipulator, which automatically grabs the oil seal servo and presses it into the casing, monitored by a pressure displacement curve system;

5. Use barcode scanners and code readers to read barcode information such as tooling, ship plates, and materials, and bind production data to facilitate traceability inquiries and quality analysis;

6. The equipment has a modular, standardized, and flexible design, which on the one hand is conducive to the maintenance, repair, and maintenance of the equipment, and on the other hand, provides convenient conditions for subsequent model changes that may be needed;

7. The yield rate is over 99%, and the utilization rate can reach 90%.

With the transformation and upgrading of the manufacturing industry and the rapid development of intelligent manufacturing, the performance and quality requirements of oil pump motors are also constantly improving. Oil pump motor production line equipment is becoming increasingly intelligent, enabling more precise control and monitoring, improving the operating efficiency and reliability of the equipment, and bringing a better user experience to customers.

Related News