News Center

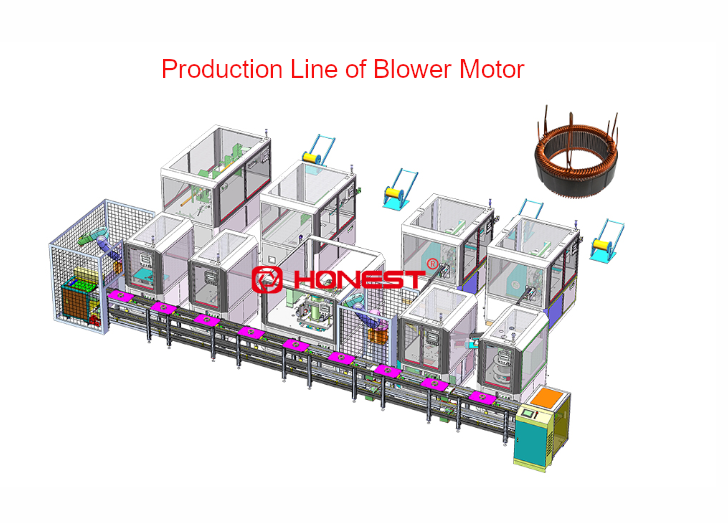

An Outline of HONEST’s Blower Motor Automated Assembly Line

Published on.

2024-08-20 18:00

Source

Introduction to Blower Motors

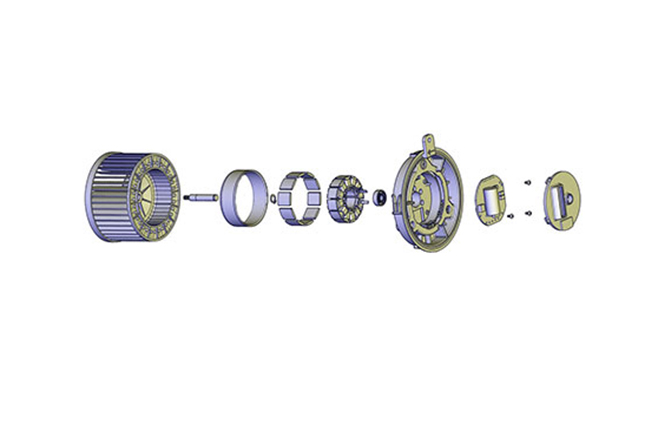

A blower primarily consists of six components: the blower motor, air filter, blower casing, air chamber, base, and oil drip nozzle. Blowers can generally be categorized into Roots blowers, blast furnace blowers, magnetically levitated blowers, single-stage high-speed centrifugal blowers, and multi-stage centrifugal blowers.

As national energy-saving and environmental protection policies are effectively implemented and the industry’s technical level continues to advance, the demand for energy efficiency in blower equipment will become increasingly stringent. Blowers that are energy-efficient, high-performance, and low-noise will be more favored by the market. Therefore, high-performance blower motors are crucial.

HONEST is an experienced manufacturer of blower motor assembly lines, with a rich history in manufacturing. The following is a detailed introduction to the equipment in the general assembly section and the controller assembly section of the motor assembly line.

Key Production Equipment

A.Stator and Rotor Assembly Machine

HONEST’s stator and rotor assembly machine utilizes precise production processes, from spring assembly to clip assembly, with each step meticulously designed to ensure product quality and reliability. The machine is equipped with photoelectric sensors for missing part detection and error-proofing, limit switches for verifying travel, and inductive sensors for detecting missing springs and retaining rings, all of which, combined with a fixed setup, ensure the stability and accuracy of the assembly process as well as the traceability of production data.

Functionally, the machine achieves automation from rotor automatic grabbing and feeding to spring vibratory bowl automatic feeding, in conjunction with sensors and limit switches, to ensure error-proofing and fool-proofing during the production process. Pressure curve monitoring, along with automatic pressing and spring force testing, further ensures the precision of the assembly.

In terms of equipment configuration, it is equipped with a barcode reader, missing part detection, dimension inspection, and automatic rejection of defective products, ensuring the continuity of the production process and the consistency of product quality.

B.Bearing Cover and Seal Plug Assembly Machine

The equipment can precisely assemble the bearing cover and seal plug. It performs missing part detection and, through a series of sensors and inspection devices, achieves error-proofing and fool-proofing of the product, ensuring that each product meets quality standards. Additionally, the use of a barcode reader and scanning gun ensures traceability of work information, facilitating the supervision of the product process.

Advantages of Bearing Cover and Seal Plug Assembly Machine:

1.High level of automation: From feeding, scanning, and pressing, to the rejection of defective products, all are automatically completed by the machine. This can greatly save labor, improve production efficiency, and thus ensure the production of the entire line.

2.Servo Pressing and Displacement Detection: The pressing process of the cover is completed by a servo press, and the pressing position of the cover is detected by a displacement sensor, ensuring the accuracy of the pressing position.

C.Motor Assembly Harness Machine

Key Processes:

1.The production process of the harness assembly locking machine covers two key processes: harness feeding and assembly, as well as locking. Automated operations, ensure the consistency of the process and the precision of the assembly.

2.Flexible Feeding: The harness is preliminarily positioned by a suction disk, and the harness material disk is automatically transported to the specified position by an AGV vehicle, reflecting the flexibility and convenience of our feeding system. It is equipped with a robotic arm and vision guidance to automatically grab the harness, ensuring the accuracy of feeding.

3.Locking Process: The locking mechanism automatically tightens the harness screws, achieving synchronous locking at both ends and improving work efficiency.

All the above steps reflect the intelligent automation and flexibility of HONEST’s motor assembly harness machine equipment, which can effectively improve work efficiency and ensure the continuity of the production process.

D.Motor Silicone Sheet Applicator

The equipment process: Completes the application of silicone sheets to the motor.

1.Intelligent Feeding: After manual loading of the silicone sheet roll, the machine automatically separates the sheets and recovers the protective film. The silicone sheet is then picked up by the equipped needle and vacuum suction cup, and automatically applied to the motor, reducing manual involvement and improving operational accuracy.

2.Vision Inspection System: The equipped vision inspection system checks whether the silicone sheet is accurately applied. If it exceeds the preset deviation value, it is automatically directed to the defective product area. The preset value can be customized according to the actual production requirements of the customer.

E.PCB Feeding & Optical Inspection Machine

Key Processes

1.Automated Feeding and Storage: PCBs are fed using a vacuum suction disk packaging method, ensuring material consistency as the initial direction of the feed is predetermined. AGV vehicles are then used for automatic feeding, with a storage time of up to 1 hour, providing reliable material transportation support for the production line.

2.Precise Feeding and Positioning: Materials are transported smoothly by a conveyor belt, and the vacuum suction disk partition mechanism achieves automatic lifting and partitioning, along with the cooperation of a robotic arm and vision-guided automatic PCB grabbing and placement for inspection, ensuring precision and efficiency in placement.

3.Empty Disk Recovery: After completing their function, the vacuum suction disks are automatically grabbed and offloaded to the empty disk area. When the empty disks reach a set number of layers, they are neatly stacked and sent out by the conveyor belt, achieving efficient material management.

Inspection Equipment

A.Back EMF Tester

This tester is primarily designed for back electromotive force (EMF) testing and insulation to withstand voltage testing to ensure the motor operates stably under any working conditions. Additionally, by reading the QR code on the motor, production information can be traced, effectively improving the efficiency of production management and providing data support for product quality tracking.

The equipment ensures the accuracy of the product during testing through mechanisms such as sensors, thereby enhancing the credibility of the test results. Products that fail the test are automatically directed to the defective product area.

B.Selective Wave Soldering, Cleaning, and AOI Inspection Machine

1.Wave Soldering: After the motor is automatically loaded, it and the harness are clamped and flipped to ensure accurate positioning for soldering. The motor and harness are placed on the wave soldering jig, and the harness is secured to ensure stability during the soldering process.

2.Suction Cleaning: After the soldering work is completed, the product is vacuumed to remove impurities generated during the soldering process, ensuring product cleanliness.

3.AOI Inspection: The soldering quality is automatically inspected using the AOI system to ensure that the soldering meets the standard.

C.Motor Performance Tester

The motor performance tester is a key piece of equipment for ensuring the quality and performance of the motor. Through a series of automated testing actions, it can improve the efficiency and accuracy of the test results.

1.Component Fixing: Before testing, the harness and motor are fixed to ensure stability during the testing process and the accuracy of the test results.

2.Automatic Power Test: The equipment conducts a load test on the motor at room temperature, testing the speed under different currents to ensure that the motor performance meets the set standards.

3.Noise Test: Under no-load conditions, the equipment automatically powers the motor for noise testing and is equipped with vibration sensors to monitor the motor’s vibration, assessing the stability of the motor’s operation.

HONEST’s blower motor automated production line is highly intelligent and capable of effectively improving production efficiency for customers, saving labor and time costs. To ensure the high quality and consistency of the products, we strictly control the operations of each process and are equipped with corresponding automated testing equipment, which enhances the efficiency of the testing actions and ensures the reliability and accuracy of the test results. Additionally, HONEST offers non-standardized customization services, and the inspection standards at each stage can be set according to your actual production needs to ensure that the products meet your quality requirements.

If you have any requirements for blower motor production lines or individual machine equipment, please feel free to contact us at any time. We will provide you with more detailed information and a preliminary quotation

Related News