News Center

Choose the Right Brushless Stator Winding Equipment

Published on.

2024-10-16 15:16

Source

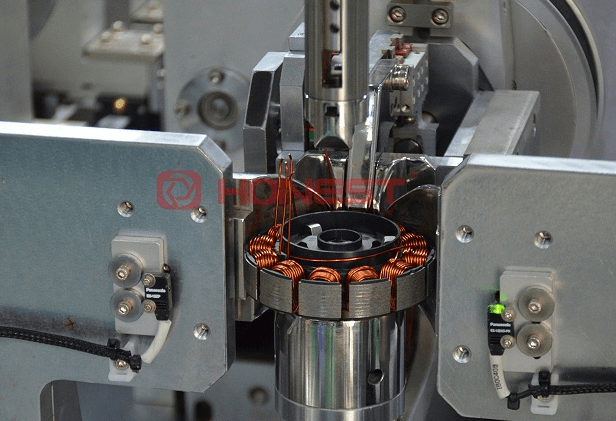

In the field of motor stator manufacturing, stator winding and stator wire arrangement technology are crucial. Among them, winding and wire arrangement equipment are divided into ordinary stator winding equipment and precision stator wire arrangement equipment according to the product precision requirements. There are differences between the two in terms of performance, application range and manufacturing process. The structure of ordinary stator winding equipment is relatively simple, mainly including winding machine, winding mold and control system. Wire winding is achieved by adjusting the parameters of the winding mold, which is suitable for products with large wire diameter and low precision requirements. The structure of precision wire arrangement equipment is more complex, mainly including wire arrangement machine, wire arrangement mold, control system and visual inspection system. Accurately control the movement of the wire arrangement mold to achieve precise arrangement of wires, which is suitable for products with small wire diameter and high precision requirements.

1. Difference in accuracy: Ordinary stator winding equipment usually has certain difficulties in accurately controlling the number of winding turns, and there may be problems such as uneven winding and inconsistent spacing. During the winding process, the control of the wire diameter is not accurate enough, which is prone to deviations. The precision wire arrangement equipment has extremely high control accuracy for the number of turns. With the help of high-precision counting sensors and intelligent control systems, it can accurately control the position and spacing of each winding circle to ensure the neatness and consistency of the winding. For thin or thick wires, high-precision and accurate wire arrangement can be achieved, making the quality of the product more reliable.

2. Speed comparison: For some products with simple structure, fewer turns and low requirements for wire arrangement precision, the speed advantage of ordinary wire winding is more obvious. In contrast, precision wire arrangement equipment is more in line with the winding requirements of complex products. Although its speed is not as fast as that of ordinary wire winding equipment when winding simple products, it can achieve a relatively considerable wire arrangement speed while ensuring high precision with its advanced control system and precise mechanical structure, and complete the winding task in a relatively stable state. It is precisely because of its excellent stability and reliability that precision winding equipment has become the first choice in many high-end manufacturing fields.

3. Degree of automation: The automation level of ordinary winding equipment may be relatively low, and often requires a certain degree of manual intervention and adjustment. For example, when replacing the bobbin or adjusting the winding parameters, the operator may need to perform manual operations. Precision wire arrangement equipment usually has a high degree of automation. It can achieve automatic detection, automatic adjustment and automatic error correction through advanced sensors and control systems. This not only improves production efficiency, but also reduces the impact of human factors on product quality.

As the motor manufacturing industry has higher requirements for precision and efficiency, there are significant differences between ordinary winding and precision wire arrangement equipment in terms of structure, performance, and manufacturing process. When choosing equipment, companies should make reasonable selections based on product precision, production efficiency, and other requirements.

Shenzhen HONEST Intelligent Equipments Co., Ltd. was established in 2007. It started with independent research and development of customized winding machines and accumulated experience in the field of winding machine technology. The company can not only provide high-performance, high-quality precision stator winding machine to meet the needs of the global market, but also pay attention to listening to the voice of customers and ensuring the perfect fit between products and applications through non-standard customized design. At the same time, it is also committed to providing digital and intelligent motor equipment overall solutions for new energy vehicles, automotive electric parts, rail transit, aviation, home appliances, industry, robots and other industries, providing strong support for the intelligent upgrade and high-quality development of the global motor manufacturing industry.

Next page

Related News