News Center

Starter Motor Assembly Solutions for Automotive Industry

Published on.

2025-05-04 14:16

Source

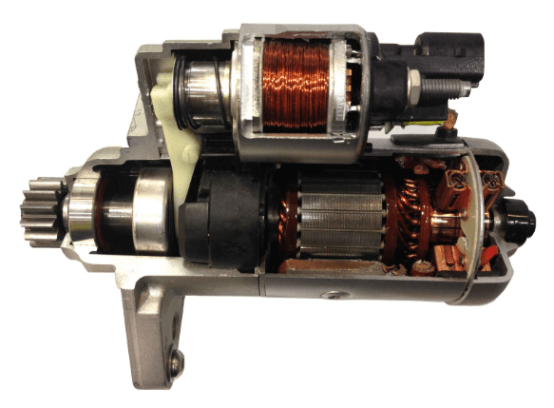

As global automotive technologies evolve and vehicle platforms diversify, the demand for efficient, reliable, and high-precision starter motor assembly has become a strategic focus for automakers and motor suppliers. Whether supporting internal combustion engine (ICE) vehicles or hybrid electric vehicle (HEV) systems, the performance of a starter motor directly impacts vehicle start-up reliability, fuel efficiency, and overall driving experience.

At HONEST Automation, we deliver advanced starter motor assembly automation solutions tailored to the needs of today’s automotive industry—offering integrated systems, process stability, and flexible customization to support both high-volume production and complex product variation.

1. The Role of Starter Motors in Modern Vehicles

The starter motor is a DC motor designed to rotate the engine’s crankshaft, initiating the combustion process. In ICE and HEV vehicles, its reliability is critical. Some key features of starter motors include:

High torque output for cold starts

Durability under frequent use (especially in stop-start systems)

Integration with vehicle control systems for smart ignition

As vehicles adopt more intelligent and energy-saving systems, the starter motor assembly must meet stricter quality, noise, and durability standards.

2. Understanding the Starter Motor Assembly Process

Starter motor assembly typically involves the following steps:

A. Armature Winding

Copper wire is precisely wound onto the rotor core using flyer winding or needle winding machines.

Critical parameters: number of turns, coil tension, wire layering accuracy.

B. Commutator Welding

The coil ends are connected to the commutator using TIG welding or resistance welding.

Ensures low resistance and reliable electrical connectivity.

C. Shaft Pressing and Balancing

The rotor shaft is pressed into the core with strict alignment tolerances.

Dynamic balancing is performed to reduce vibration and noise during operation.

D. Magnet Assembly

Permanent magnets are inserted into the motor housing (in PMDC designs).

Requires robotic precision to ensure placement and magnetic polarity alignment.

E. Final Housing Assembly

Stator, rotor, brushes, bearings, and casing are assembled.

Automation ensures consistent torque application and precise component placement.

F. End-of-Line Testing

Electrical tests: resistance, insulation, back EMF

Mechanical tests: noise, vibration, dynamic performance

Optional: barcode/QR code traceability system integration

Every process requires tight process control, inline monitoring, and traceable data collection—which are difficult to achieve with manual assembly.

3. Common Challenges in Manual Starter Motor Assembly

Despite its historical use, manual or semi-manual assembly lines face several limitations:

Inconsistent product quality due to human variability.

Low takt time (cycle time), limiting production throughput.

High labor cost and operational training requirements.

Difficulty in scaling to different product designs.

Risk of quality recalls due to a lack of traceability.

Automated solutions are rapidly becoming the standard in an industry driven by zero-defect goals and lean manufacturing.

4. HONEST’s Starter Motor Assembly Automation Solutions

With over 19 years of expertise in motor automation equipment, HONEST provides customized starter motor assembly lines designed for automotive-grade reliability. Our solutions cover:

Full and Semi-Automated Production Lines

For various starter motor types: 12V/24V DC, PMDC, BLDC, HEV-specific

Modular design for flexible station configuration

Intelligent transport systems for smooth material flow

High-Precision Winding Machines

Needle winding, flyer winding, or toroidal winding options

Integrated wire feeding, tension control, and quality monitoring

Capable of multi-slot, segmented winding patterns

Advanced Welding and Assembly Stations

Commutator welding: TIG/resistance with real-time monitoring

Shaft and bearing pressing with servo-controlled force and displacement sensors

Automatic magnet insertion with visual guidance

End-of-Line Testing & Data Traceability

Fully automated EOL testers with multi-point inspection

Auto-sorting of OK/NG parts

Data storage compatible with MES systems

Options for barcode printing and scanning

5. Key Benefits of HONEST’s Automation Solutions

By choosing HONEST, automotive manufacturers can expect:

Increased Productivity – Reduce cycle time, improve output

High Accuracy & Repeatability – Meet Tier 1/OEM precision standards

Real-Time Quality Control – Ensure each process meets tolerances

Fast Product Switchover – Support multi-type motor platforms

Global Service Support – Remote diagnostics, training, and spare parts

Whether you need a single specialized machine or a complete turnkey production line, HONEST provides design-to-delivery support tailored to your factory layout, motor design, and output needs.

6. Real Applications in the Automotive Industry

Our starter motor assembly solutions are widely used in:

Passenger vehicle starter systems

Commercial truck and bus motors (24V)

Micro-hybrid (stop-start) systems

Two-wheeler and light electric vehicle starter motors

Starter-generator units for hybrid platforms

We’ve delivered production lines for leading motor manufacturers, Tier 1 suppliers, and EV startups across Asia, Europe, and the Americas.

7. Why Choose HONEST Automation as Your Equipment Partner?

19+ years of experience in automotive motor automation

Customized design capability for different motor structures

Expert engineers and localized after-sales support

Successful partnerships with global motor brands (OEM & Tier 1)

Fast delivery and commissioning of production lines

We don’t just sell machines—we deliver complete, scalable, and future-ready solutions.

In a highly competitive automotive market, upgrading to automated starter motor assembly is not just a productivity move—it's a strategic investment in product quality, manufacturing intelligence, and long-term cost efficiency.

If you're seeking a reliable, innovative partner for your next project, HONEST will help you build a smarter, faster, and more competitive assembly line.

Contact us now to discuss your starter motor automation needs.

Previous page

Related News