News Center

The Human-Machine Interaction System Architecture and Features of the Servo Press Machine

Published on.

2025-05-08 14:33

Source

In the field of precision manufacturing in modern industrial production, servo press machines have become indispensable key equipment in many industries, such as automotive parts manufacturing, electronic device assembly, and aerospace, due to their high precision and high flexibility.

The servo press machine ensures stable product quality through precise pressure and displacement control, from packaging precision chips to assembling automotive engine components. Behind the operation of the servo press machine, the human-machine interaction system serves as the core control hub, connecting every step of the equipment's operation and providing solid support for the intelligent upgrade of industrial production.

Function of the Human-Machine Interaction System: Building the Bridge Between People and Equipment

Operating Control Center

During operation, personnel can easily start and stop the servo press machine through this system, and also precisely set various process parameters during the assembly process, such as setting pressing pressure, speed, displacement, and more.

Information Interaction Hub

The human-machine interaction system architecture plays a key role in the information exchange of the servo press machine. On one hand, it serves as the window for operators to input commands, whether it's starting the equipment, adjusting parameters, or switching production programs, all of which are completed through this interface. On the other hand, it is the terminal for outputting equipment status, providing real-time operation data, fault warnings, and other information in a visualized format to the operator. The bidirectional interaction mode breaks down the communication barriers between people and equipment, making the complex assembly process intuitive and controllable.

Equipment Management Platform

The human-machine interaction system architecture in the servo press machine allows for access control, setting different levels of user permissions to ensure that only authorized personnel can perform critical operations and parameter settings. This not only ensures the safe operation of the equipment but also prevents equipment failures and production accidents caused by incorrect operations.

HONEST's servo press machine also features a human-machine interaction system architecture, with the following advantages and characteristics:

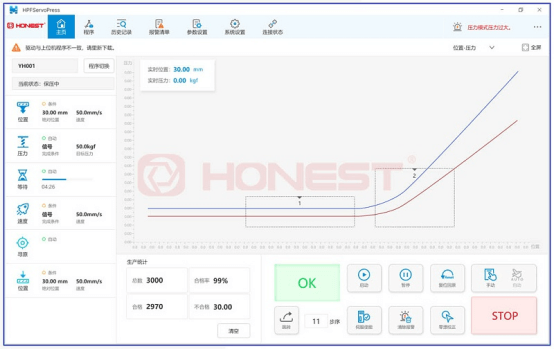

Ultra-high Sampling Frequency: During the pressing process, the servo press machine can rapidly record data such as position, pressure, and speed, allowing it to precisely capture every detail of the operation. The maximum sampling frequency reaches up to 200Hz, simultaneously collecting data from three channels—position, pressure, and speed. All data points can be exported to Excel for review.

Rich Curve Display Modes: Multiple curve display options are available, including “Position-Pressure,” “Position-Speed,” “Time-Position,” “Time-Pressure,” and “Time-Speed.” The system also displays the curve inspection window and its evaluation results.

Simple and User-friendly Interaction Experience: The graphical interface is intuitive and easy to use. It clearly displays the current status of the press machine, the step currently being executed, the production result of the current product, and production statistics.

Extremely Low Operating Threshold: With graphical programming logic, users can simply piece together different functional modules to execute a complete and coherent pressing sequence. Even those with no prior experience can quickly get started.

Highly Flexible Programming: Each step can be configured with different functional modules and completion conditions, and the parameter settings between steps are completely independent. The system supports up to 64 pressing steps.

Collaboration with External Devices: The system can interact with external equipment via IO or Modbus communication. Each step can be individually configured with trigger conditions and output signals, enabling synchronized operation with external devices.

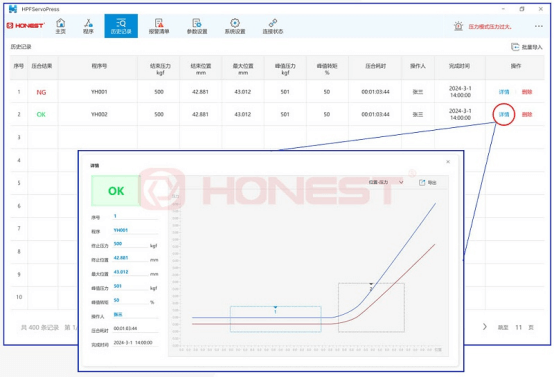

Automatic Generation of Historical Data Files: Each time a pressing task is completed, a historical record is automatically created and stored locally in the touch panel PC as a file, making it easy to archive and review.

Quick Record Traceability: Historical records can be quickly retrieved by date, program number, or pressing result. Curves and complete production data can be directly viewed on the history page for fast access.

So, why is the human-machine interaction system considered the core control hub of the pressing process in a servo press machine? The following industry application example highlights its significance:

(1) Automotive Manufacturing Industry: In the pressing processes of key components such as automotive engines and transmissions, the requirements for pressing precision and quality control are extremely high. The human-machine interaction system enables fast operation control, seamless program switching, and implementation of automated production workflows, which significantly shortens the production cycle and improves equipment utilization and production efficiency. Meanwhile, precise parameter control and real-time quality monitoring functions help ensure the stability and consistency of the pressing process, thereby improving product quality and yield rates.

(2) Electronics Manufacturing Industry: Components in electronic devices are typically miniaturized and highly precise, placing strict demands on pressure control and positional accuracy during the pressing process. The human-machine interaction system meets the high-precision requirements for pressing tiny components, ensuring accurate installation and reliable connections. Additionally, the system’s data recording and traceability functions help electronics manufacturers meet product quality traceability and regulatory compliance requirements.

With the development of artificial intelligence, the Internet of Things, and digital twin technology, the human-machine interaction system has become a critical component in the operation of servo press machines, thanks to its core functions such as operation control, information exchange, safety protection, and system integration. It not only enhances the level of equipment automation but also enables transparent and intelligent production through data-driven processes, providing strong technical support for cost reduction and efficiency improvement. In the future, human-machine interaction systems will evolve rapidly toward greater intelligence and visualization, becoming a key force in driving the technological advancement of servo press machines and the intelligent transformation of industrial production.

As a provider of intelligent motor equipment solutions, HONEST is committed to delivering digital and intelligent integrated solutions, as well as intelligent vision inspection servo press systems, to a wide range of industries including new energy vehicles, rail transit, automotive electric components, humanoid robots, low-altitude aircraft, home appliances, and industrial applications.

If you are looking for a servo press assembly solution, feel free to leave a message on the official website of Shenzhen HONEST Intelligent Equipment Co., Ltd. We will follow up within 24 hours and respond quickly to your needs.

Related News