News Center

Domestic Servo Press Machine to Tackle EV Motor Assembly?

Published on.

2025-05-09 08:20

Source

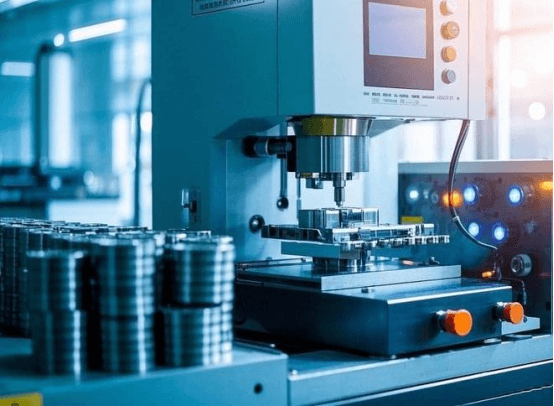

In modern industrial production, the servo press machine plays a crucial role in press-fitting, offering precise and efficient assembly of various components. Its stable performance is essential across automotive manufacturing, electronics production, and mechanical processing.

The precise press-fitting capability of servo press machines not only enhances product consistency and reliability but also ensures stable product quality. For example, in the assembly of automotive components, a servo press machine can accurately press critical parts like bearings and gears into place, minimizing damage caused by improper fitting and reducing the defect rate significantly.

Let's now take a look at the specific applications of servo press machines in various case scenarios.

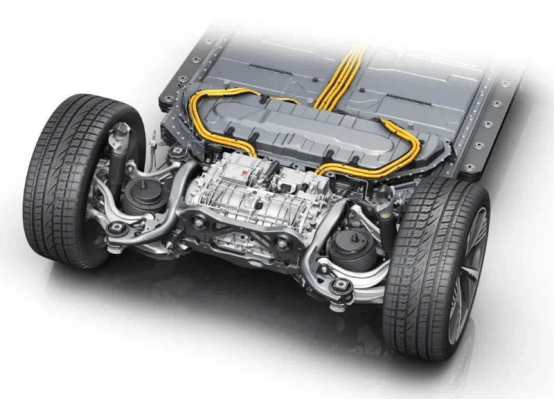

Automotive Industry: In automotive motor assembly lines, servo press machines are commonly used for installing pistons and connecting rods. They precisely control pressure and displacement according to preset press-fitting curves, ensuring that the gap between the piston and the connecting rod remains within a very tight tolerance range.

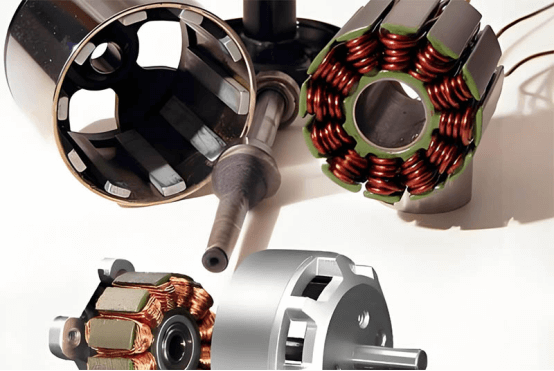

Home Appliance Industry: For example, in the production of air conditioner compressors, the servo press machine is primarily responsible for pressing the motor rotor into the stator. Its precise press-fitting technology ensures the concentricity between the rotor and stator, improving the compressor's operating efficiency and cooling performance, while also extending its service life.

Machinery Industry: The assembly of key machine tool components, such as the spindle, requires the precise operation of a servo press machine. It accurately presses in components like bearings and seals, ensuring the high-precision rotation of the spindle, which is crucial for the accuracy of machining processes.

Although servo press machines are widely used in various fields, they also face several manufacturing challenges in practical applications, such as press-fitting penetration and precision.

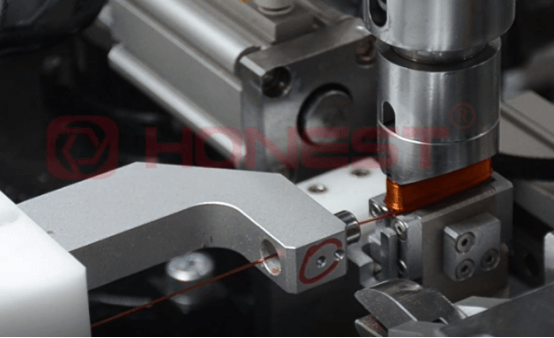

Taking automotive motor assembly as an example, when a standard servo press machine is used for pressing the motor rotor and stator, a common issue is low press-fitting penetration. This means the contact surface between the rotor and stator is not tight enough, leading to problems such as excessive noise and current fluctuations during motor operation, which affects the motor's performance and lifespan. Additionally, deviations in press-fitting precision can result in unstable motor performance, making it prone to failures during high-speed operation.

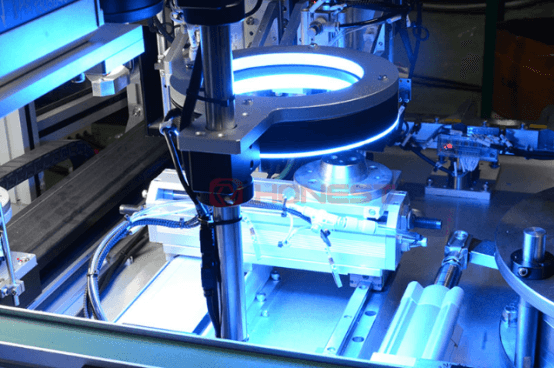

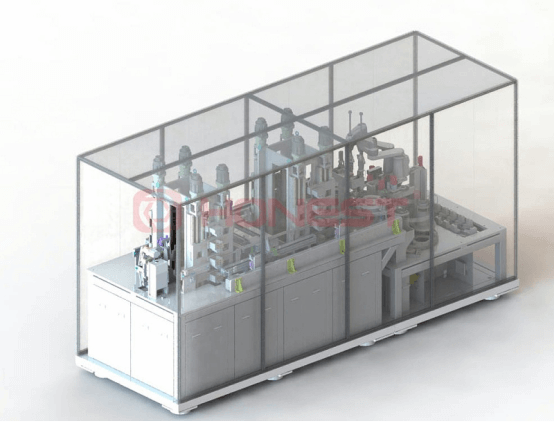

To address the issues in automotive motor assembly, Honest Automation's self-developed servo press machine has implemented a series of innovative measures. By using an advanced control system, it can monitor parameters such as pressure and displacement in real-time during the press-fitting process. Meanwhile, intelligent algorithms precisely control and adjust the press-fitting curve, significantly improving press-fitting penetration and precision.

Additionally, in the application of automotive motor assembly, Honest Automation's servo press machine ensures a tight fit between the rotor and stator through higher pressure control precision, faster closed-loop response speed, more flexible press-fitting programming, and easier operation. This results in smoother motor operation, effectively reducing motor failure rates and improving the overall performance and reliability of automotive motors. For automotive motor manufacturers, this not only lowers defect rates and after-sales repair costs but also boosts production efficiency and product quality, enhancing the company's competitiveness in the market.

With its outstanding performance and wide range of applications, the importance of the servo press machine is increasingly evident across various industrial sectors. As the manufacturing industry continues to upgrade and develop, higher demands are being placed on the functionality and performance of servo press machines. In the future, servo press machines will play an even greater role in smarter, more automated production lines, achieving even more precise press-fitting processes.

We will continue to innovate and develop solutions in servo press machines and intelligent motor equipment, dedicated to providing digital and intelligent integrated solutions for industries such as new energy vehicles, rail transportation, automotive electric components, humanoid robots, low-altitude aircraft, home appliances, and industrial sectors. At the same time, by continuously optimizing the performance of servo press machines, we aim to improve press-fitting precision and efficiency, helping manufacturing enterprises enhance their production capabilities, drive the intelligent transformation of industrial production, and contribute to the high-quality development of industrial manufacturing.

Related News