News Center

Top 5 Issues in Hairpin Motor Manufacturing

Published on.

2025-07-31 10:27

Source

Hairpin motor, known for its high power density, energy efficiency, and compact design, has become a key technology in new energy vehicle (NEV) manufacturing and industrial automation. However, despite their advantages, manufacturers often encounter a series of technical and process-related challenges during production. These obstacles can lead to lower efficiency, higher production costs, and even compromised product quality.

This article provides a systematic analysis of the most common pain points in hairpin motor production, drawing from past technical experience and industry data. We also share practical solutions to help manufacturers optimize production lines, improve output, and ensure product reliability.

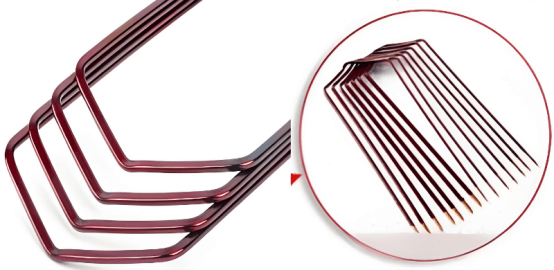

Pain Point 1: Low Precision and Poor Consistency in Hairpin Wire Forming

Hairpin wire forming is one of the most critical processes in hairpin motor manufacturing. The accuracy of wire forming directly affects the quality of coil insertion and the overall motor performance. However, traditional equipment often struggles with inconsistent bending angles, dimensional deviations, and surface damage to copper wires during the bending and shaping stages.

These issues lead to poor winding alignment, increased insertion difficulty, and ultimately reduced motor efficiency and reliability. Achieving high precision and consistency in hairpin wire forming is therefore essential for ensuring product quality and stable mass production.

Solution: High-Precision Forming with Flexible 2D/3D Universal Wire Bending Machine

To address the challenges in wire forming, manufacturers can adopt a universal wire bending machine equipped with integrated 2D/3D forming technology and a high-speed 4-axis robotic arm. This advanced system enables flexible and precise production of various hairpin wire types—including H-pin, X-pin, and Mini-pin—on a single production line.

The equipment features an automated tool magazine with 36 sets of forming dies, allowing for seamless switching between wire shapes. With its rapid 5-second die changeover capability, the machine significantly improves production flexibility, reduces downtime, and ensures consistent forming accuracy for high-performance motor applications.

Pain Point 2: Low Insertion Efficiency and Complex Process

The hairpin winding insertion process is inherently more complex than traditional round wire insertion. In many cases, it still relies heavily on manual operation, resulting in low productivity and a high risk of human error. Common issues include loose windings, inter-turn short circuits, and inconsistent alignment, all of which negatively impact the electrical performance and reliability of the motor.

Solution: Precision-Formed Preforms for Efficient Insertion

The universal wire bending machine not only excels at shaping but also enhances the insertion process. Producing hairpin wires with high dimensional accuracy, precise angles, and smooth, flat terminal ends ensures optimal compatibility with stator slot insertion and press-fitting operations. These high-quality preforms significantly reduce insertion errors, streamline the assembly process, and lay a solid foundation for automated high-speed motor production.

Pain Point 3: Unstable Welding Quality—Prone to Cold Soldering and Detachment

The welding quality between the hairpin winding and the terminal is critical to ensuring electrical conductivity and long-term motor reliability. However, traditional welding methods—such as manual soldering or standard resistance welding—often result in weak joints, large heat-affected zones (HAZ), and inconsistent weld quality. These problems increase the risk of cold solder joints, cracks, or even complete disconnection under vibration or thermal cycling.

Solution: High-Energy Laser Welding for Precision and Strength

To ensure stable and high-quality connections, high-energy laser welding is recommended. This advanced technique offers a narrow heat-affected zone, uniform weld seams, and strong bonding strength, making it ideal for precision welding of highly conductive materials such as copper. Laser welding not only enhances connection reliability but also supports automation and repeatability, which are essential for mass production of high-performance hairpin motors.

Pain Point 4: Difficult Insulation Process—Risk of Coil Damage

Insulation treatment is a critical step in hairpin motor manufacturing. During processes such as varnish dipping and curing, improper process control can lead to damaged insulation layers, uneven coating, or incomplete penetration. These defects severely compromise the dielectric strength and service life of the motor.

Solution: Vacuum Varnishing with Precision Control

To enhance insulation quality and consistency, a vacuum trickle impregnation system can be used. This system enables precise stator tilting and controlled resin flow, allowing varnish to penetrate deep into the windings without leaving any dead zones. Combined with precision pump-valve metering and high-frequency heating, this solution ensures a high slot fill rate, uniform insulation, and reliable performance in large-scale production.

Pain Point 5: Slow Production Cycle and Poor Equipment Compatibility

Hairpin motor manufacturing involves multiple complex processes, including wire forming, insertion, welding, insulation, and testing. In traditional setups, poor coordination between equipment often leads to production bottlenecks, low equipment utilization, and inconsistent takt time, making it difficult to meet high-volume manufacturing demands.

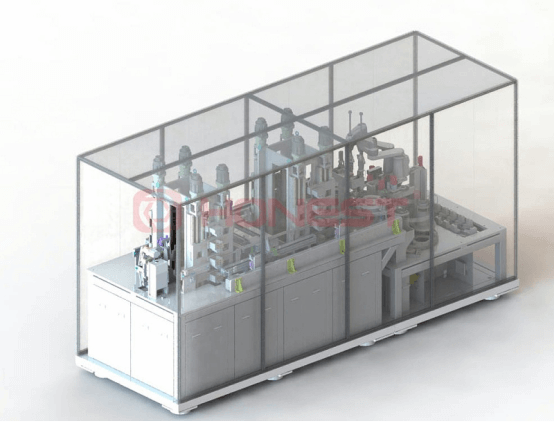

Solution: Fully Integrated Automation and High-Speed Forming

A fully integrated automated production line—covering wire forming, insertion, welding, insulation treatment, and final testing—ensures seamless connection between all key processes. This eliminates handoffs, reduces downtime, and enables stable, high-throughput production.

In addition, the dual-channel wire forming machine delivers exceptional efficiency with a cycle time of just 1.2 seconds per wire, producing up to 3,000 hairpins per hour. This represents a 100% increase in productivity, while maintaining high accuracy and repeatability to support mass production of hairpin motors.

The main challenges in hairpin motor production lie in forming precision, insertion efficiency, welding quality, insulation processing, and line integration. Leveraging years of deep expertise in intelligent motor manufacturing, HONEST Automation offers a series of high-efficiency, intelligent, and reliable solutions designed to help manufacturers effectively address these critical pain points.

Our solutions not only enhance production efficiency and product quality but also empower enterprises to achieve technological breakthroughs and market leadership in the new energy motor industry.

For more information about hairpin motor or automotive motor production equipment, please feel free to contact us online.

Related News