News Center

In Motor Assembly Lines, Quality Starts Long Before Final Inspection

Published on.

2025-08-04 15:19

Source

Is Inspection Equipment Essential in Motor Assembly Lines?

At first glance, this might seem like an obvious question in the manufacturing world — of course, it is.

But beneath this simple answer lies a deeper truth: as smart manufacturing continues to evolve, traditional quality control methods based on manual inspection and operator experience are becoming obsolete. In modern motor production, ensuring consistent quality requires fully integrated inspection systems powered by automation, digitalization, and intelligent technologies throughout the entire assembly process.

Amid this transformation, inspection equipment plays a critical role in motor assembly lines — not just as a quality control checkpoint, but as a key factor in ensuring product consistency, long-term performance, and operational safety under high-load, continuous-use conditions.

In fact, the strength of a manufacturer’s inspection capabilities has become a key indicator of whether the company possesses true high-end motor manufacturing expertise.

If inspection is so important, why does it still need to be discussed?

Because recognizing its importance doesn’t necessarily mean it’s well understood — or properly implemented.

In working with various clients, we’ve observed a common pattern: many manufacturers acknowledge the value of inspection equipment, yet often misapply it in practice. Some invest heavily in redundant inspection stations, driving up costs without improving results. Others, in an attempt to cut spending, rely solely on final-stage testing — effectively gambling on quality at the last possible moment.

So what is inspection equipment, really?

A tool for post-process quality checks, or a core element of in-process control?

A cost burden — or a strategic investment in long-term product quality?

Let’s examine two real-world scenarios to gain a better understanding of the issue.

Scenario 1: Inspection After Every Process Step

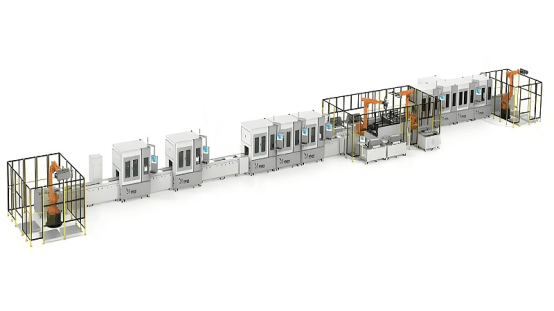

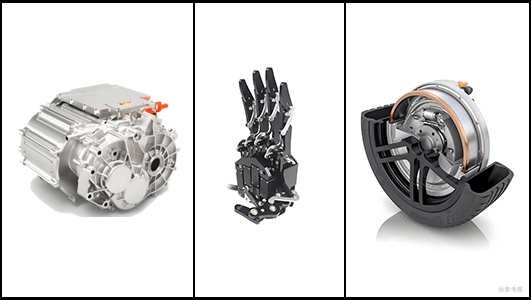

In some motor manufacturing environments, inspection equipment is installed after every single production step. This approach is commonly found in companies producing motors for high-safety, high-reliability applications — such as electric vehicle drive motors, industrial robot joint motors, and traction motors for rail transit.

In these sectors, even a minor quality failure can result in critical safety incidents. That’s why every process is tightly monitored, and inspection is treated as a non-negotiable safeguard throughout the production line.

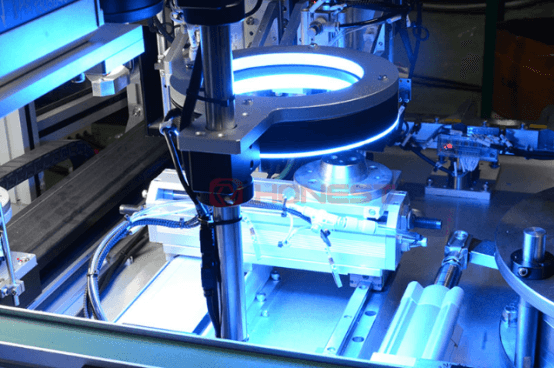

That’s why manufacturers in these high-stakes sectors install inspection equipment at every critical process point. This allows them to detect assembly issues in real time and prevent defects from passing to the next stage. Key parameters — such as assembly precision, electrical performance, and mechanical tolerances — are continuously monitored to ensure each step meets strict quality standards.

Their philosophy is clear: Quality isn’t something you inspect into a product at the end — it’s built in at every stage.

However, this level of precision isn’t always practiced correctly. In fact, we often see two common missteps:

The first is overengineering inspection.

Some manufacturers install inspection stations indiscriminately at every step — including non-critical ones — without a clear quality strategy. This results in misallocated resources, redundant data, and increased operational burden, without improving actual product quality.

This reflects a fundamental misunderstanding: More inspection equipment doesn't necessarily mean better quality — what matters is deploying it where it truly counts.

The second is relying solely on the final-stage inspection.

On the other end of the spectrum, some companies conduct quality checks only at the finished product stage. This is more common among manufacturers targeting cost-sensitive or lower-tier markets, where safety requirements are less stringent. Their priority is to minimize manufacturing costs and shorten the return-on-investment cycle — often at the expense of proactive quality control.

However, this “final-stage only” inspection approach carries significant risks.

Imagine a stator defect that occurs during one of the earlier assembly steps — but isn’t detected until the very end of the process. By that point, you’re not just dealing with a single issue — you’re looking at wasted components, extensive rework, or even full-batch scrap. The cost and time impact can be substantial.

Furthermore, the lack of in-process inspection means manufacturers lose the ability to monitor process stability in real-time. Product consistency becomes difficult to maintain, and when quality issues arise, the absence of detailed process data makes root-cause analysis slow and challenging.

Over time, this lack of visible process control erodes customer confidence. You can’t prove that every motor was carefully verified — only that a batch passed final testing. In high-end markets, where trust and traceability are essential, this becomes a critical weakness.

After analyzing these two real-world scenarios, a natural question arises:

Does every single process step truly require dedicated inspection equipment?

The answer is — not necessarily.

Not all process steps require physical inspection, but every critical stage must be under control.

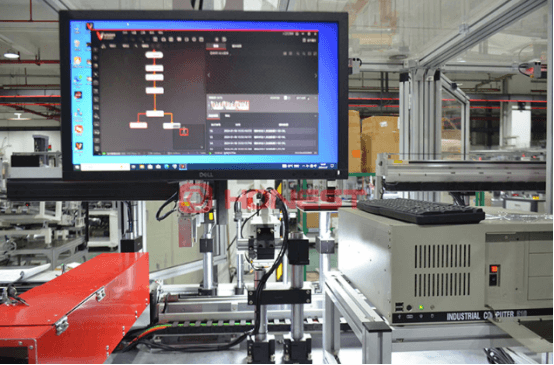

As intelligent manufacturing systems continue to evolve, quality assurance is shifting from reactive “end-of-line inspection” to proactive strategies based on process visibility, data-driven decision-making, and predictive risk management. In this new paradigm, traceability systems are no longer optional add-ons — they have become core infrastructure supporting the entire quality framework.

Even for manufacturers looking to control costs, robust traceability and data systems can still provide full visibility into product quality — enabling precise problem identification, process control, and root-cause traceability without relying on excessive physical inspection points.

So, what role does this traceability system actually play?

We can understand it through four straightforward dimensions.

Comprehensive Recording of Process Parameters:

The system captures and stores real-time data of every assembly action, including key parameters such as torque, pressure, displacement, and time — creating a complete and continuous data chain.

Rapid Issue Identification and Root Cause Analysis

When a quality issue arises, the system enables fast traceability to the exact machine, operation, and abnormal parameter — helping manufacturers accurately pinpoint the root cause.

Continuous Process Optimization

By analyzing historical data, manufacturers can continuously refine process parameters to improve overall production efficiency and product yield.

Reliable Quality Assurance

Even without physical inspection equipment at every step, the system can generate detailed data reports, providing a trustworthy endorsement of product quality.

From these four dimensions, it’s clear that traceability systems not only complement inspection equipment effectively but also embody a new quality control philosophy — one driven by data to achieve comprehensive control over the entire production process.

Therefore, when considering whether every process step must have inspection equipment, it’s critical not to fall into the trap of indiscriminate installation. Instead, inspection points should be strategically and scientifically deployed. The true focus is not on simply “having inspection,” but on the ability to control the process, trace issues back to their source, and proactively prevent risks.

This reflects HONEST Automation’s position as a supplier of intelligent motor assembly solutions. We recommend installing inspection equipment at select critical process stages — not out of doubt in our own manufacturing capabilities, but because we have full confidence in the precision and stability of our equipment. We choose to use both inspection and data validation to demonstrate our commitment to high standards, rigorous quality, and continuous improvement. This is both a responsibility and a promise.

Of course, we fully understand that every customer has different product positioning, capacity planning, and cost structures. That’s why HONEST Automation’s solutions are always designed to be flexible, customizable, and tailored to meet diverse client needs.

Finally, let’s return to the opening question:

Is inspection equipment important in motor assembly lines?

The answer remains a resounding yes.

However, its significance should not be reduced to a simple matter of presence or absence — it should be elevated to how inspection equipment is used effectively and strategically.

Inspection equipment serves not only as the “eyes” controlling the assembly process but also as the “sentinel” advancing quality upstream, and as a vital “chain of evidence” that builds customer trust.

Inspection equipment is a means to achieve quality control — not the end goal itself. What truly determines product quality is a company’s quality culture, accumulated process expertise, systematic thinking, and data governance capabilities.

At HONEST Automation, we firmly believe that quality is not something to be “inspected in,” but something to be built in through rigorous control of every detail.

Whether our clients choose to equipment inspection stations at every process step or rely on robust traceability systems for in-process monitoring, HONEST Automation commits to delivering intelligent motor assembly solutions characterized by high quality, consistent performance, and superior energy efficiency.

Because for HONEST Automation, we’re delivering more than just equipment — we’re delivering a deep respect and commitment to product excellence.

Previous page

Related News