News Center

Why are Hub Motors not Mass-Produced?

Published on.

2025-06-03 10:45

Source

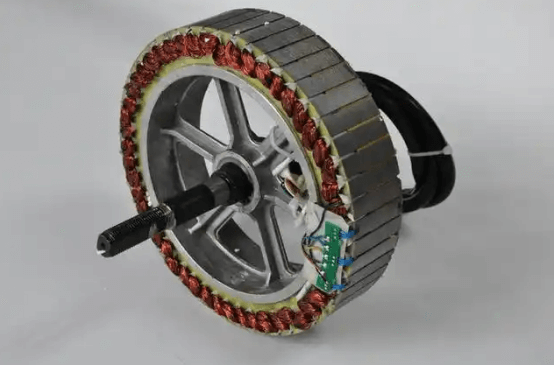

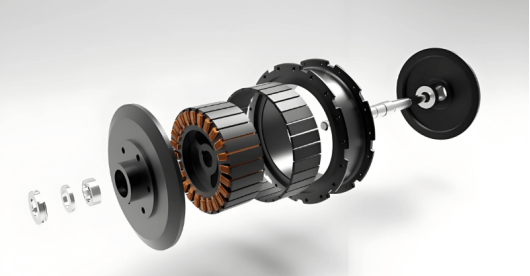

As an emerging automotive drive technology, wheel hub motor have many applications and important roles. They integrate the power, transmission, and brake systems into the wheel hub to form a highly integrated drive unit.

In the field of new energy vehicles, it eliminates the need for traditional transmission components such as the clutch, gearbox, drive shaft, and differential. This simplification of the vehicle structure reduces weight, improves space utilization, and enhances transmission efficiency. Not only does it enable a more efficient and environmentally friendly approach to vehicle propulsion and power delivery, but it also offers a range of significant advantages:

High Integration: The hub motor integrates the drive, transmission, and braking systems directly into the wheel hub, eliminating the need for numerous complex transmission components. This significantly simplifies the vehicle structure and offers greater flexibility in vehicle design and layout.

Ease of Control: Since the motor directly drives the wheels, the Motor Control Unit (MCU) can precisely control wheel speed and torque with simple commands. This allows for high control accuracy. Additionally, differential steering can be achieved by varying the speed—or even reversing the direction—of the left and right wheels. This reduces the vehicle's turning radius, enables on-the-spot rotation, and enhances the efficiency of regenerative braking.

Modular Advantage: Thanks to its high level of integration, the hub motor is theoretically only dependent on wheel size, making it easier to implement modular designs. This avoids repetitive development efforts, shortens the development cycle of new vehicle models, and reduces R&D costs.

Compatibility with Multiple Drive Types: Hub motors are compatible with a wide range of vehicle types—including battery electric vehicles (BEVs), fuel cell electric vehicles (FCEVs), range-extended electric vehicles (REEVs), and conventional hybrid electric vehicles (HEVs). They can serve as either the main propulsion source or as auxiliary power, while also supporting technologies such as regenerative braking with ease.

Challenges to Mass Production: Despite its many advantages, hub motors have yet to be widely adopted in mass production. One of the main challenges is the increased unsprung mass. Since the motor is mounted inside the wheel, it adds to the unsprung weight, which can make the suspension system less responsive. This negatively affects ride comfort, vehicle dynamic response, and the balance of traction during acceleration, braking, and cornering—ultimately reducing the vehicle’s overall handling performance.

Thermal Management Challenges: Hub motors generate a significant amount of heat during operation, but due to their installation within the wheel hub, effective heat dissipation is difficult to achieve. The limited space and exposure to external elements make thermal management a major engineering challenge.

Sealing and Reliability: Due to their unique position, hub motors are often exposed to harsh road conditions and environments. This requires excellent sealing performance to prevent the ingress of water, dust, and other contaminants. At the same time, they must maintain high reliability to withstand long-term road vibrations and shocks, placing significant demands on the motor's quality and durability.

Incomplete Supply Chain Support: The industrialization of hub motors depends on synchronized support from the entire upstream and downstream supply chain. However, the current lack of adequate suppliers for related components makes it difficult to meet large-scale production demands. In addition, shortcomings in prototype development and stable supply capacity have also constrained the mass production progress of hub motors.

As a revolutionary vehicle propulsion technology, hub motors demonstrate significant advantages and development potential in the field of new energy vehicles, even though they have yet to be mass-produced. With ongoing technological advancements and gradual industrial support, hub motors are expected to become a key option in future automotive drive systems, ushering in new transformations and growth opportunities for the industry.

HONEST Automation: Supporting the Future of Hub Motor Production

As a leading provider of intelligent motor manufacturing equipment, HONEST Automation plays a vital role in the assembly and production of hub motors. Backed by advanced technology and extensive experience in the motor equipment industry, we are committed to delivering high-precision, high-efficiency intelligent equipment to motor manufacturers. Our automated production lines and testing systems significantly improve the quality and consistency of hub motor production, helping companies overcome technical bottlenecks in manufacturing and accelerating the broader market adoption of hub motors.

Related News